December 31, 2014

Mostly, all optical amplifiers are used in optical communication. Generally, Brillouin type amplifier is not used in optical communication. For a particular use, the decision has to be made about which amplifier to be used. The EDFA amplifier is used in-line amplifier on account of its compatibility. On the other hand, CATV amplifier will be a very good power amplifier because of its high saturation.

EDFAs and conventional lasers, achieve gain by pumping atoms into a high energy state. This allows the atoms to release their energy when a photon of a suitable wavelength passes nearby. RFAs utilize Stimulated Raman Scattering (SRS) to create optical gain. Because SRS robs energy from shorter wavelengths and feeds it to longer wavelengths, high channel count DWDM systems initially avoided this technique.

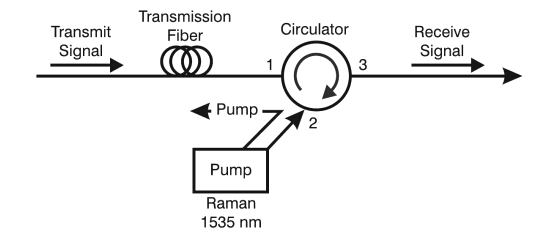

A RFA amplifier consists of little more than a high-power pump laser, usually called a Raman laser, and a WDM or directional coupler. The optical amplification occurs in the transmission fiber itself, distributed along the transmission path. With amplification up to 10 dB, RFAs provide a wide gain bandwidth (up to 100 nm), allowing them to operate using any installed optical fiber (single mode optical fiber, TrueWave, etc.). By boosting the optical signal in transit, RFAs reduce the effective span loss and improve noise performance.

Combined with EDFAs, RFAs create a wide gain-flattened optical bandwidth. The figure belwo shows the topology of a typical RFA. The pump laser and optical circulator comprise the two key elements of the RFA amplifier. In this case, the pump laser has a wavelength of 1535 nm. The optical circulator provides a convenient means of injecting light backwards into the transmission path with minimal optical loss.

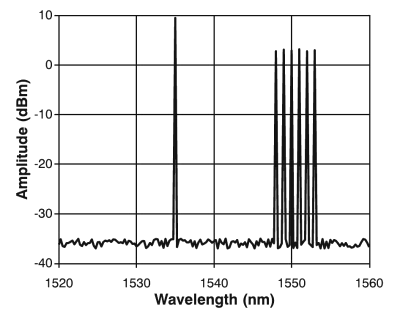

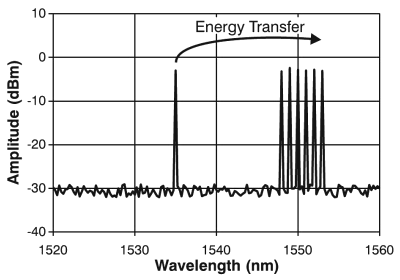

Here are the figures which show the optical spectrum of a forward-pumped RFA amplifier and the received signal after the same length of fiber used in the SRS example. The signal gets injected by the 1535 nm pump laser at the transmit end rather than the receive end. Generally, the amplitude of the pump laser exceeds that of the data signals.

With a significant decrease in the amplitude of the pump laser, the amplitude of the six data signals has increased, giving all six signals roughly equal amplitudes. In this case, the SRS effect robbed a great deal of energy from the 1535 nm pump laser signal and redistributed that energy to the six data signals.

Fiber Optic Network is a method of transmitting information from one place to another by sending pulses of light through an optical fiber. Fiberstore, backed by China factories, supplies a complete series of products for fiber optic networking, such as passive WDM (Wavelength Division Multiplexing) modules (including CWDM, DWDM, OADM, etc.), multimode fiber splitter, optical amplifiers, optical attenuators, CWDM & DWDM transceivers, transponders, and active CWDM & DWDM equipment. Our singlemode& multimode FBT optical splitter comes in a wide range of split ratios with single/double/three windows. You can get complete solutions from Fiberstore when you build or expand fiber optic network capacity.

More fiber optic network information can go to fiberopticshare blog, designs, manufactures, and sells a broad portfolio of optical communication products, including passive optical network, or PON, subsystems, optical transceivers used in the enterprise, access, and metropolitan segments of the market, as well as other optical components, modules, and subsystems.

Posted by: kelonlau at

04:10 AM

| Comments (15)

| Add Comment

Post contains 554 words, total size 5 kb.

December 30, 2014

Fiber optic patch cable, a quite simple but necessary fiber optic products in our optical network, all people who works in the fiber optical industry almost have some knowledge about it. It mainly includes a fiber optic cable and a connector on its end parts, and this kind of fiber optic cable is used to communicate with different optical devices or other electronic devices for transmitting the signal, since these points, we can believe that has different types, different connectors, different lengths, different applications and so on. However, these differences can help me choose what we need and today this page will explain fiber patch cables from different aspects and hope this page give you some helps.

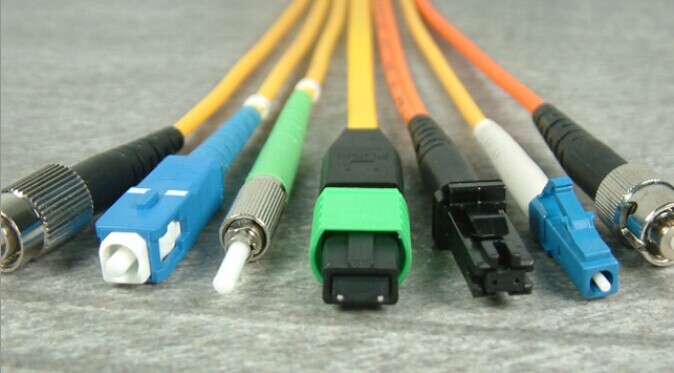

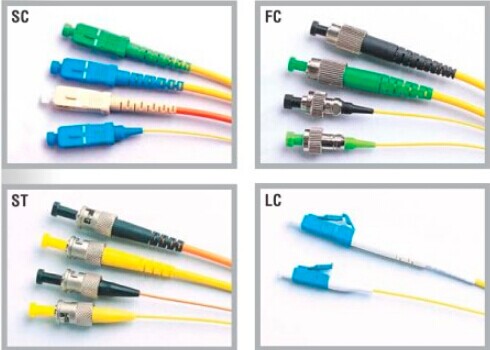

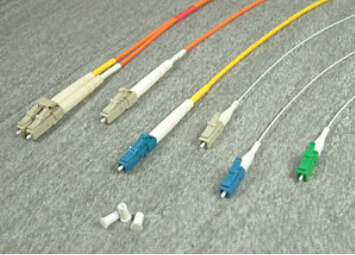

Firstly, we must have it in mind is fiber optic connector, as you know, at its end parts we can see that many different connectors, the commonly used connectors are ST, SC, LC, MT-RJ, FC, MU, SMA, ESCON, FDDI and etc…, well, the two sides all can be different, it just means such as LC to ST fiber patch cable, FC to sc fiber patch cable and others. Fiber application for fiber optic connectors can be singlemode and multimode patch cable, we usually see it and it sometimes abbreviation as SM and MM patch cable. Of course, they can have different options, for example, singlemode lc to lc fiber patch cord or multimode FC to SCfiber patch cable… The Figure show four common types of fiber connectors.

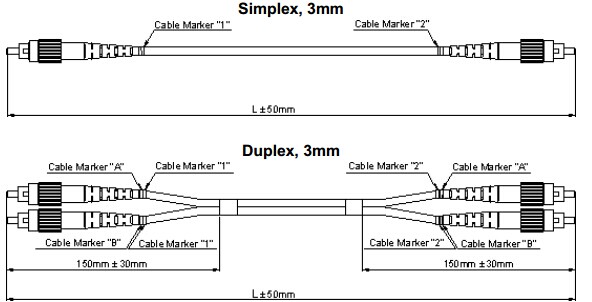

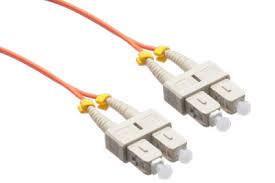

As for the the differences between singlemode and multimode fiber optic cables, singlemode is an optical fiber cable with a small core (eg 2-9 microns) that supports one mode and multimode is an optical fiber with a core (25-200 microns) that supports several mode and the core size is also different, commonly SM is 8.3/125 and multimode is 62.5/125, except this, singlemode used to high speed, long distance links and multimode used for lower speed and short distance links. Then another category is usually forgotten, the mode conditioning fiber cables, it is specific to gigabit ethernet applications, all these cables are not interchangeable. By the way,there are some types we have to mention it, it is simplex and duplex cable, simplex cable has a single fiber and duplex cable has two fibers and they usually in zipcord (side by side) style, simplex 3mm and duplex 3mm are shown as the Figure.

Secondly, the jacket types are we also nend to know, available jacket types are PVC riser, ofnp plenum, indoor and outdoor riser, indoor and outdoor plenum, aerial and direct burial, waterproof fiber optic patch cords, ribbon fiber optic cables and bunched fiber optic cables. In Fiberstore, PVC/lszh patch cables category are OM1, OM2, OM3 cables and OM4 fiber cables, and the OM3 and OM4 provide data transfer speeds of 10G in 10Gbe high bandwidth applications via OM4 fiber, it is faster than equal μm OM2 fiber, and the OM1 and OM2 fiber cables in Fiberstore all multimode fiber cables.

Finally, the pulling eye option is also important, it is the end of the cable to prevent damage during installation. During the fiber optic installation, the force is redirected to the body of the cable instead of the core or connectors, this reduces the stress and damage to the fibers, it maybe removed and reused. They are used in telecommunication network, active device termination, CATV networks and local area networks.

Well, when we know some knowledge of fiber patch cables, and the next step we need to know where to buy it, there is a quite good site for you, Fiberstore will be you good choice, it has professional solution to provide for you and high quality fiber cables to supply, include bare fiber adapter and even fiber optic pigtails, more to say, Fiberstore is doing big sales for the festal arrival, if there are some needs, welcome to have a try.

Related Article: Overview Of 16 Gbps Fiber Channels

Posted by: kelonlau at

03:47 AM

| Comments (10)

| Add Comment

Post contains 664 words, total size 6 kb.

December 25, 2014

The 100BASE-FX fiber optic media system provides all of the advantages of a 10BASE-FL fiber optic link segment, while operating ten times faster. Distances of 2 km (6561.6 feet) over multimode fiber optic cables are possible when operating 100BASE-FX segments in full-duplex mode. Considerably longer distances are possible when using single mode fiber segments. This is why the 100BASE-FX media system is a popular choice for Ethernet backbone networks.

The following set of media components are used to build a 100BASE-FX fiber optic segment:

â— Fiber optic cable.

â— Fiber optic connectors.

Fiber Optic Cable

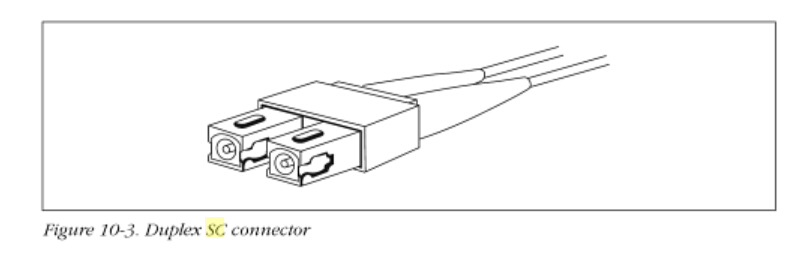

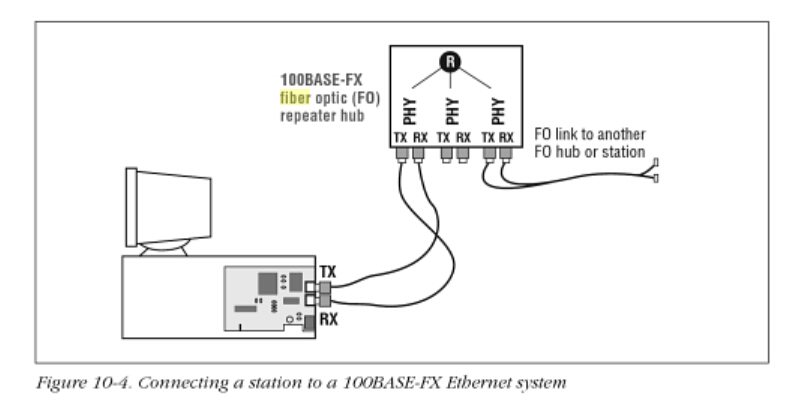

The 100BASE-FX specification requires two strands of multimode fiber optic (MMF) cable per link, one for transmit data, and one for receive data, with the signal crossover (TX or RX) performed in the link as shown in Figure 10-4. There are many kinks of fiber optic cables available, ranging from simple two-strand jumper cables with PVC plastic for the outer jacket material on up to large inter-building cables carrying many fibers in a bundle.

The typical fiber optic cable used for a 100BASE-FX fiber link segment consists of a graded-index MMF cable. These fibers optic cables have a 62.5 um fiber optic core and 125um outer cladding (62.5/125). The wavelength of light used on a 100BASE-TX fiber link segment is 1350 nanometers (nm). Signals sent at that wavelength over MMF fiber can provide segnment lengths of up to 2000 meters (6561 feet) when operating the link in full-duplex mode. More details on installing and using fiber optic cables and connectors can be found, Fiber optic patch cable and connectors.

Fiber Optic Connector

The medium-dependent interface (MDI) for a 100BASE-FX link may be one of three kinks of fiber optic connector. Of the three, the duplex SC connector shown in Figure 10-3 is the recommended alternative in the standard an is the one most widely used gy vendors. The SC connector is designed for ease of use; the single mode fibre cable with lc connector is pushed into place and automatically snaps into the connector housing to complete the connection.

The ST connector may also be used. This is the same connector used for a 10BASE-FL link. It is a spring-loaded bayonet-type connector that has a key on an inner sleeve and an outer baynoet ring. To make a connection, you line up the key on the inner sleeve of the ST plug with a corresponding slot on the ST receptacle, then push the connector in and lock it in place by twisting the outer bayonet ring.

According to the standard, the FFDI fiber optic media interface connector (MIC) may also be used on 100BASE-FX equipment: however, this optional connector has not been adopted by equipment vendors.

Connecting a Station to 100BASE-FX Ethernet

Figure 10-4 shows a computer equipped with a 100BASE-FX Ethernet adapter. In this example, the adapter card comes with an SC duplex connector, which makes a connection to the fiber cables that connect to the repeater hub. The repeater hub in the figure is shown with three pairs of 100BASE-FX SC connectors and built-in transceivers. A signal crossover is required to make a connection between the 100BASE-FX transceiver in the station, and the 100BASE-FX transceiver located in each repeater or switching hub port.

Fiberstore as the main professional fiber optic products manufacturer in china offer a various kinds of fiber cable connectors, FC Connectors, LC Connectors, SC Connectors, MPO Connectors and ST Connectors. You can buy fiber optic connection products on our store with your confidence. All of fiber optics supplies with high quality but low price. Except fiber optic connector, we provide various types of fiber patch cords including single mode, multimode, multi core, and armored versions. You can aslo find fiber optic pigtails and other special patch cables here. For most of them, the SC, ST, FC, LC, MU, MTRJ, E2000, APC/UPC connectors are all available, even we supply MPO/MTP fiber cables.

Article Source: http://www.fiber-optic-components.com/100-base-fx-mdeia-components.html

Posted by: kelonlau at

07:07 AM

| No Comments

| Add Comment

Post contains 658 words, total size 6 kb.

December 23, 2014

Quite often it is desirable to have a means of connecting two fibers together through a temporary mating device or connector. Figure 7.4 shows a common way to implement such a connector. Each fiber is placed in a ferrule whose function is to provide the mechanical support for the fiber and hold it in place tightly. The ferrule can be made out of plastic, metal, or ceramic materials. The central piece of the connector itself is an alignment sleeve. The two ferrules are inserted in the sleeve, and proper alignment between the cores is ensured because of the tight mechanical tolerances of the ferrules and the sleeve. The gap between the two fibers can be controlled by a mechanical stop which determines the exact stopping positions of the fibers. In some variations, the alignment sleeve is tapered to improve connector mating and demating.

Well-designed connectors provide low coupling loss, in the order of 0.1 dB or less. However, as shown in Fig. 7.5, a number of underirable situations can reduce the coupling efficiency. Figure 7.5a shows a case of two fibers with different core diameters. In general, whenver the numberical apertures of two fibers are different, the potential for power loss exists. In this case, light coupling from a narrower fiber core to a wide fiber core is easier and more efficient compared to coupling in the other direction. Figure 7.5b shows an example of poor concentricity. Fibers that do not provide a tigh concentricity tolerance may show large coupling variations depending on the orientation or from one pair of fibers to the next.

A large air gap, shown in Fig 7.5c, is another reason for loss of power. An air gap can result from incomplete insertion of the fiber or from mechanical problems inside the sleeve. It is also common for microscopic dust particles to get into fiber optic connector, preventing them from making proper conatact, or even scratching and damaging the fiber facets.

More dramatic power reduction results when dust particles land on the fiber core, blocking the light path. As a result, constant monitoring and cleaning of fiber facets are important to prevent such probems. Angular or lateral displacement, the mechanical tolerances are not tigh enough or when the dimensions of the sleeve and the ferrule do not match.

A fiber connector is characterized by several important parameters. As noted before, the most important factor is insertion loss, or simply connector loss. Another important factor is repeatability. If the same two fibers are connected through the same connector a number of times, each time the coupling will be slightly different. A good connector assmbly provides a small standard deviation for coupling efficiency across multiple insertions. Another desiralbe specification of a fiber connector is low return loss, i.e., a low back reflection. Return loss is defined as the ratio of the reflected power from the connector to the input power. For example, a return loss f 30 dB means 0.001 of the input power is reflected back from the connector. A conector must also be resistant and show a minimal coupling variation in the presence of normal mechanical forces such as axial and lateral forces. This is a practical requirement because in a normal environment it is likely for the connector to encounter a range of mechanical forces.

A wide range of connectors have been designed and are in use in the industry. Here we give an overview of some of the most popular types.

Straight tip or ST connectors are one of the more common type of connectors and in wide use in many applications. The ferrule diameter in an ST connector is 2.5 mm. ST connectors are spring loaded and enaged by a twist-and-lock mechanism.

Fixed connector or FC connectors use an alignment key and a threaded (screw-on) socket and are similar to the popular SMA connectors used in electronics. They are in wide use in single-mode applications and provide low insertion loss and high repeatability.

Subscriber connector, or SC, is another common type of connector. The advantage offibre optic sc connectoris that they are engaged by a push-and-snap mechanism, without the need for any roation. This make plugging and unplugging them very easy and also reduces wear out. Moreover, a higher connector density is achieved. Many transceivers provide either an SC receptacle connector, or a pigtail SC connector, as their optical interface. The push-and-snap feature of SC connectors thus provides very convenient and easy way of connecting to optical trasceivers. SC connectors are avaiable in simplex and duplex variations. The ferrule diameter in an SC connector is 2.5 mm.

SC fiber optic patch cable is one of the earliest stype and one of the most commonly used fiber optic cable, it is convenient to use and cost saving, SC fiber optic patch cord is widely uesed in fiber optic networks. SC fiber patch cable is with zirconia sleeve and plastic housing. The common type of SC connector patch cord, there are SC to SC fiber patch cord, SC to LC fiber optic patch cable, SC to ST Fiber Optic Patch Cable, SC to FC Fiber Optic Patch Cable, ect.

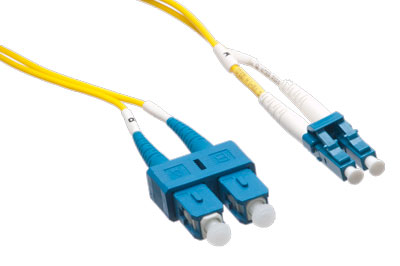

The LC or small form factor connector is similar to the SC, but with half the size. The diameter of the ferrule in an LC connector is 1.25 mm, vs 2.5 mm for most other connectors. This allow for twice the connector density for a given space. Because of their compactness, LC connectors have become more popular and are used in many high-end transceivers such as SFPs and XFPs. lc to lc duplex single mode is with a small form factor (SFF) connector and is ideal for high density applications. LC fiber optic patch cord connector has a zirconia ceramic ferrule measuring 1.25mm O.D. with a PC or APC endface, and provides optimum insertion and return loss.

We carry singlemode and multimode optical fiber patch cables with a variety of connector types such as LC, SC, ST, and MTRJ. Duplexfiber optic patch cableconsist of two fiber cores and can be either multimode or singlemode. This dual core system allows for the bi-directional transfer of data, as opposed to simplex fiber cables, which typically only propagate data in one direction. The exception being Wavelength Division Multiplexing (WDM) systems in which bidirectional communication is acheived over singlemode simplex fiber using multiple wavelengths. In our "How-To†section you will find step-by-step instructions on how to terminate fiber optic cable.

Article Source:http://www.cables-solutions.com/connectorized-couplings.html

Posted by: kelonlau at

07:22 AM

| No Comments

| Add Comment

Post contains 1074 words, total size 8 kb.

December 22, 2014

There are many different fiber optic connection methods, connector types, and ways to terminate them, single-mode and multimode connectors create differences in the types and methods used as well. If you plan to work with fiber optics, you should perform in-depth research about fiber before attempting to terminate it. In fact, it is best to take a course in fiber optic cable termination or learn from an expernt.

When terminating fiber and adding connectors, there are two main connector type to chosse from: SC and ST. There are many other connection types (fiber has been around since the early 1970s) that have been developed through the years, but to limit the scope of this book to what is most widely used on data networks today, you need to be thoroughly familiar with the SC and ST connectors.

SC is a snap-in connector, meaning that you place it in a receptacle, such as on a network switch, and click it into place; this is also called stick and click. The SC connector is shown in Figure 8.14.

SC connector are a relatively new connector-type technology, but are in popular use today. Part of their popularity is that are cheaper and easier to use than ST connectors, and less prone to damage. You will most likely see thesee types of connections from large core swiches with fiber uplinks to smaller closet swiches in campus network.

As we know, SC patch cable is with SC connector which was invented by NTT. It is widely used fiber optic patch cables. SC fiber optic patch cable has low cost and good durability, SC fiber optic patch cables is with a locking tab on the cable termination, it is a push and pull type optical connector. The common SC patch cable we have seen, there are SC to FC, SC to SC adss fiber, SC to ST, and SC to LC.

ST Connector

ST (which is an old AT&T trademarked technology) is another type of fiber connection type. Like the BNC connector for coaxial cable, it has a bayonetbased mounting end and a long cylindrical ferrule, which is spring-loaded sheath used to hold the fiber in place. You insert the connector into a receptacle and twist it to lock it into place. Stick and twist considered an older technology, but is still widely used on data networks, and its install base is broad. An ST connector is shown in Figure 8.15

Real-world production enviroments (especially when working with Cisco Systmes, Nortel Networks) do not include ST in new implementations. In most cases, the only way to use this order technology is with a mediation device, such as a transceiver, which has one end that plugs into an attachment unit interface (AUI) port and an ST-based mounting connection on the other end.

To facilitate installation of our active fiber equipment we support a large selection of fiber optic patch cords. The always in stock fiber cables include optical connectors such as: SC, ST, LC and FC type, simplex and duplex. Our patch cords range from 0.5m to 10m and have almost all available combination of optical connectors. The most available lengths are 1m, 2m, 3m, 5m, and 10m patch cords. All single-mode patch cords are UPC polished (Ultra Physical Contact), while the multi-mode cables are PC polished. All fiber patch cords are manually tested and verified and each patch cable is individually sealed and labeled with measured optical performance.We offer competitive price for fiber optic patch cable, our company has strictly quality control system and high quality products,the custom fiber patch cable is fast delivery to worldwide customers.

Article Source: http://www.cables-solutions.com/two-main-connector-type-sc-and-st.html

Posted by: kelonlau at

09:20 AM

| No Comments

| Add Comment

Post contains 611 words, total size 4 kb.

December 19, 2014

The LC connector developed by Lucent Technologies and shown in Fig.3.10 is a more evolutionary approach to achieving the goals of a SFF connector. The LC connector utilizes the traditional components of a SC duplex connector having independent ceramic ferrules and housings, with the overall size scaled down by one-half. The LC family of connectors includes a stand-alone simplex design; a "behind the wall†(BTW) connector and the duplex connector available in both single-mode and multimode tolerances are all designed using the RJ-style latch.

The outward appearance and physical size of the LC connector varies slightly depending on the application and vendor preference. Although all the connectors in the LC family have similar latch styles modeled after the copper RJ latch, the simplex version of the connector has a slightly longer body than either the duplex or BTW version, and the latch has an additional latch actuator arm that is designed to assist in plugging as well to prevent snagging in the field. The BTW connector is the smallest of the LC family and is designed as a field-or board-mounatable connector using 900-um buffered fiber and in some cases has slightly extended latch for extraction purposes. The duplex version of this connector has modified body to accept the duplexing clip that joins the two connector bodies toghther and actuates the two latches as one. Finally, even the duplex clip itself has variations depending on the vendor. In some cases the duplex clip us a solid one-piece design and must be placed on the cable prior to connectorization, while other design and must be placed on the cable prior to connectorization, while other designs have slots built into each side to allow the clip to be installed after connectorzation. In coclusion, all LC connectors are not created equal, and depending on style and manufacturer’s preference, there may be attributes that make one connector more suitable for a specific application then another.

The LC duplex connector incorporates two round ceramic ferrules with outer diameters of 1.25mm and a duplex pitch of 6.25mm. These ferrules are aligned through the traditional couplers and bores using precision ceramic split or solid sleeves. In an attempt to improve the optical performance to better than 0.10 db at these interfaces, most of the ferrule and backbane assemblies are designed to allow the cable manufacturer to tune them. Tuning of the LC connector simply consists of roating the ferrule to one of four available positions dictated by the backbone design. The concept is basically to align the concentricity offset of each ferrule to a single quadrant at 12.00; in effect, if all the cores are slightly offset in the same direction, the probalility of a core-to-core alignment is increased and optimum performance can be achieved. Although this concept has its merits, it is yet another costly step in the manufacturing process, and in the case where a tuned connector is mated with an untuned connector, the increase in performance may not be realized.

Typically, the LC duplex connectors are terminated onto a new reduced-size zipcord referred to as mini-zip. However, as the product matures and the applications expand, it may be found on a number of different cordages. The mini-zip cord is one of the smallest in the industry with an outer diameter of 1.6mm compared with the standard zipcord for an SC style product of 3.0 mm. Although this cable has passed industry standard testing, the cable manufacturers have raised some issues concering the ability of the 900-um fibers to move freely inside a 1.6-mm jacket and others involving the overall crimped pull strengths. For these reasons, some end users and calbe manufactures are opting for a larger 2.0-mm, 2.4-mm, or even the standard 3.0-mm zipcord. In application wher the fiber is either protected within a wall outlet or cabinet, the BTW connector is used and terminated directly onto the 900-um buffers with no jacket protection.

The factory termination of the LC cable assemblies is very similar to order ceramic-based ferrules using the standard pot and polish processes with a few minor differences. The one-piece design of the connector minimizes production handling and helps to increase process yields when compared with other SFF and standard connector types. Because of the smaller diameter ferrule, the polishing times for an LC ferrule may be slightly lower than the standard 2.5-mm connectors, but the real production advantage is realized in teh increase number of connectors that can be polished at one time in a mass polisher. For the reasons mentioned above and because the process is familiar to most manufacturers, the LC connector may be considered one of the eaisest SFF connectors to factory terminate.

Field termination of the LC connector has typically been accomplished through the standard pot and polish techiques using the BTW connector. However, a pre-polished, crimp and cleave connector is also available. The LCQuick Light field-mountable BTW style connector made by Lucent Technologies is a one-piece design with a factory polished ferrule and an internal cleaved fiber stub. Unlike other pre-polished SFF connectors previously discussed, the LCQuick light secures the inserted field cleaved fiber to a factory polished stub by crimping or collapsing the metallic entry tube onto the buffered portion. This is accomplished by using a special crimp tool that is designed not to damage the fibers. However, light is designed specifically for use in protected environments such as cabinets and wall outlets and has no provision for outer jacket or Kevlar protection.

LC

connections allow higher density applications based on its smaller

diameter. The LC connection, commonly referred to as Lucent Connection,

Little Connector or Local Connector, is commonly used today for uplink

modules and other devices. This connector is a "snap†type, has a

ferrule diameter of 1.25mm and defined by IEC 61754-20. We offer LC

fiber cables and lc connector patch cable single mode

Posted by: kelonlau at

08:13 AM

| No Comments

| Add Comment

Post contains 1067 words, total size 7 kb.

December 18, 2014

Offering considerable improvements from previous FC speeds, 16 Gbps FC uses 64b/66b encoding, retimers in modules, and transmitter training. Doubling the throughput of 8 Gbps to 1,600 Mbps, it uses 64b/66b encoding to increase the efficiency of the link. 16 Gbps FC links also use retimers in the optical modules to improve link performance characteristics, and electronic dispersion compensation and transmitter training to improve backplane links. The combination of these technologies enables the 16 Gbps FC to provide some of the highest throughput density in the industry, making data transfers smoother, quicker, and cost-efficient.

Although 16 Gbps FC doubles the throughput of 8 Gbps FC to 1600MBps, the line rate of the signals only increases to 14.025 Gbps because of a more efficient encoding scheme. Like 10 Gbps FC and 10 Gigabit Ethernet (GbE), 16 Gbps FC uses 64b/66b encoding, that is 97% efficient, compared to 8b/10b encoding, that is only 80% efficient. If 8b/10b encoding was used for 16 Gbps FC, the line rate would have been 17 Gbps and the quality of links would be a significant challenge because of higher distortion and attenuation at higher speeds. By using 64b/66b encoding, 16 Gbps FC improves the performance of the link with minimal increase in cost.

To remain backward compatible with previous Fiber Channel speeds, the Fiber Channel application specific integrated circuit (ASIC) must support both 8b/10b encoders and 64b/66b encoders.

As seen in Figure 2-1, a Fiber Channel ASIC that is connected to an SFP+ module has a coupler that connects to each encoder. The speed-dependent switch directs the data stream toward the appropriate encoder depending on the selected speed. During speed negotiation, the two ends of the link determine the highest supported speed that both ports support.

The second technique that 16 Gbps FC uses to improve link performance is the use of retimers or Clock and Data Recovery (CDR) circuitry in the SFP+ modules. The most significant challenge of standardizing a high-speed serial link is developing a link budget that manages the jitter of a link. Jitter is the variation in the bit width of a signal due to various factors, and retimers elliminate most of the jitter in a link. By placing a retimer in the optical modules, link characteristics are improved so that the links can be extended for optical fiber distances of 100 meters on OM3 fiber. The cost and size of retimers has decreased significantly so that they can now be intergrated into the modules for minimal cost.

The 16 Gbps FC multimode links were designed to meet the distance requirements of the majority of data centers. Table 2-2 shows the supported link distances over multimode and single-mode fiber 16 Gbps FC was optimized for OM3 fiber and supports 100 meters. With the standardization of OM4 fiber, Fiber Channel has standardized the supported link distances over OM4 fiber, and 16 Gbps FC can support 125 meters. If a 16 Gbps FC link needs to go farther than these distances, a single-mode link can be used that supports distances up to 10 kilometers. This wide range of supported link distances enables 16 Gbps FC to work in a wide range of environments.

Another important feature of 16 Gbps FC is that it uses transmitter training for backplane links. Transmitter training is an interactive process between the electrical transmitter and receiver that tunes lanes for optimal performance. The 16 Gbps FC references the IEEE standards for 10GBASE-KR, which is known as Backplane Ethernet, for the fundamental technology to increase lane performance. The main difference between the two standards is that 16 Gbps FC backplanes run 40% faster than 10GBASE-KR backplanes for increased performance.

Fiberstore introduces it’s new OM4 Laser-Optimized Multimode Fiber (LOMMF) "Aqua†cables, for use with 40/100Gb Ethernet applications. These new technology, 50/125um, LC/LC Fiber Optic cables, provide nearly three times the bandwidth over conventional 62.5um multimode fiber, with performance rivaling that of Singlemode cable, at a much reduced cost. LOMMF cable allows 40/100Gb serial transmission over extended distances in the 850nm wavelength window, where low-cost Vertical Cavity Surface Emitting Lasers (VCSELs) enable a cost-effective, high-bandwidth solution. OM4 fiber optic patch cord is ideally suited for LAN’s, SAN’s, and high-speed parallel interconnects for head-ends, central offices, and data centers. Tripp Lite warrants this product to be free from defects in material and workmanship for Life. Now the following is the OM4 fiber from Fiberstore.

OM4 fiber cable lc lc multimode feature an extremely high bandwidth–4700MHz*km, more than any other mode. They support 10GB to 550 meters and 100GB to 125 meters. These cables are suitable for high-throughput applications, such as data storage. These cables are fully (backwards) compatible with 50/125 equipment as well as with 10 gigabit Ethernet applications. These connectors utilize a UPC (Ultra Physical Contact) polish which provides a better surface finish with less back reflection. With the OM4 cables, you can use longer lengths than OM3 cables while still having an excellent connection.

We offer a huge selection of single and multimode patch cords for multiple applications: mechanical use, short in-office runs, or longer runs between and within buildings, or even underground. Gel-free options are available for less mess, and Bend Insensitive cables for minimizing bend loss, which can be difficult to locate and resolve.

Article Source: http://www.cables-solutions.com/overview-of-16-gbps-fiber-channels.html

Posted by: kelonlau at

08:25 AM

| No Comments

| Add Comment

Post contains 884 words, total size 7 kb.

December 17, 2014

By mid-1999 the most widely known representative of the pilot high-density connectors was the LC connector (link control) developed by Lucent Technologies in 1997 (and by other sources in 1996). This connector is produced in both single-mode and multimode versions. It uses a ceramic ferrule with a reduced diameter of 1.25 mm and a plastic housing equipped with an external lever-type latch to fit in a coupler (Fig.4.30). The connector is produced in both simplex and duplex options.

According to existing and prospective editions of SCS standards, the optical connector designers guarantee up to 500 cycles of connections and disconnections without deterioration of loss coefficients. This is accomplished by using ceramic ferrules and by the push-pull principle of connecting the plug enables its installation on a buffered fiber (0.9mm) and on fiber patch cords in 2.4-mm loose tubes. The LC plug can be installed in field conditions on 900-mm fiber, but it can only be fabric-bonded on cables in 2.4-mm loose tubes when manufacturing patch cords because of its small dimensions.

The basic characteristics of LC connector are listed in Table.4.13.

Another version of this connector is the MU connector by NTT. This product can be considered a compact variant of the SC connector. Similar to the previous version, the MU connector has a housing with an internal latch (based on the push-pull principle). It is approximately half the size of the SC connector due to the decreased diameter of the ferrule and the miniaturization of other components. Both simplex and duplex options of the connector are commercially available.

SC fiber optic patch cable is one of the earliest stype and one of the most commonly used fiber optic cable, it is convenient to use and cost saving, SC fiber optic patch cord is widely uesed in fiber optic networks. SC fiber patch cable is with zirconia sleeve and plastic housing. Now following we recommened you some sc connector patch cords from our store.

This SC to SC fiber patch cord features 62.5/125 micron zip cord construction with two SC connectors on each end. The cable features 1.8 mm total cable width and 62.5 micron multi-mode width which is ideal for most applications including fast data networks, media extension, and other projects that require accurate, high-bandwidth signal transfers.

The sc apc to sc upc single mode 9 125 simplex fiber optic patch cord cable is terminated with one LC (male) connector and one SC (male) connector, to provide the necessary connection between fiber networking devices for high-speed, long distance networks.

Ensuring optimal data transfers and network stability, 50/125-micron cables offer nearly three times the bandwidth of 62.5/125-micron cables, so your data will be transferred at higher rates over longer distances.

We supply fiber optic patch cord , fiber optic patch cable , LC,SC/APC,ST, E2000/APC,MU, VF45,FC, MT-RJ, SC, MPO, Volition,MTP, FC/APC, ST/APC, LC/APC, E2000, DIN, D4, SMA,LSZH,Riser,Plenum,OFNR,OFNP,simplex, duplex,single mode,9/125,SM, multimode,MM, 50/125, 62.5/125.

Article Source: http://www.fiber-optic-components.com/decreased-diameter-ferrules.html

Posted by: kelonlau at

09:49 AM

| No Comments

| Add Comment

Post contains 486 words, total size 6 kb.

December 16, 2014

One of the more popular styles of fiber-optic connectors is the small form factor (SFF) style of connector. SFF connectors allow more fiber optic terminations in the same amount of space over their standard-sized counterparts. The two most popular are the mechanical transfer registered jack (MT-RJ or MTRJ), designed by AMP, and the Local Connector (LC), designed by Lucent.

MT-RJ

The MT-RJ fiber optic connector was the first small form factor fiber optic connector to see widespread use. It is one-third the size of the SC and ST connectors it msot often replaces. It had the following benefits:

â— Small size

â— TX and RX strands in one connector

â— Keyed for single polarity

â— Pre-terminated ends that require no polishing or epoxy

â— Easy to use

LC

Local Connector is a newer style of SFF fiber optic connector that is overtaking MT-RJ as fiber optic connector. It is especially popular for use which Fiber Channel adapters and Gigabit Ethernet adapters. It has similar advantages to MT-RJ and other SFF-type connectors but is easier to terminate. It uses a ceramic insert as standard-sized fiber-optic connectors do. Figure 1.21 shows an example of the LC connector. Mentioned fiber optic connector, we know fiber optic patch cords, a fiber optic patch cord is constructed from a core with a high refractive index, surrounded by a coating with a low refractive index that is surrounded by a protective jacket. Transparency of the core permits transmission of optic signals with little loss over great distances. The coating’s low refractive index reflects light back into the core, minimizing signal loss. The protective jacket minimizes physical damage to the core and coating.

Connector design standards include FC, SC, ST, LC, MTRJ, MPO, MU, SMA, FDDI, E2000, DIN4, and D4. Cables are classified by the connectors on either end of the cable; some of the most common cable configurations include FC-FC, FC-SC, FC-LC, FC-ST, SC-SC, and SC-ST.

Lc to lc fiber patch cord is used to send high-speed data transmissions throughout your network. LC/LC fiber optic cables connect two components with fiber optic connectors. A light signal is transmitted so there is no outside electrical interference. Our SC fiber optic cable is 100% optically tested for maximum performance. We have all lengths and connectors available.

Multimode LC/LC fiber optic patch cable send multiple light signals. They are 62.5/125µ. Common connectors are ST, LC, SC and MTRJ. Our 62.5/125µ LC/LC multi-mode fiber cables can support gigabit ethernet over distances up to 275 meters.

Cable Type Summary

Fiber optic patch cables are used for linking the equipment and components ,we have fiber patch cords with different fiber connector types,our low insertion loss and low back reflection .Axen Technologies fiber patch cable is widely applied in Telecommunication Networks ,Gigabit Ethernet and Premise Installations.

Posted by: kelonlau at

08:17 AM

| No Comments

| Add Comment

Post contains 468 words, total size 4 kb.

December 15, 2014

Multimode fiber systems offer flexible, reliable and cost effective cabling solutions for local area networks (LANs), Storage Area Networks (SANs), central offices and data centers. Multimode fibers support data rates from 10 and 100 Megabits per second (Mb/s) up to today’s 1 Gigabit per second (Gb/s) and 10 Gb/s applications, with standards in development to support data rates up to 40 Gb/s and 100 Gb/s.

Three types of multimode fiber are currently found in premises networks: 62.5um multimode fiber (OM1), 50um multimode fiber (OM2), and laser optimized 50ummultimode fiber (OM3). 50um and 62.5um refer to the diameter of the fiber core, which is the area that carries light signals. For the most part, OM1 fiber is found in legacy systems. Over the past five years, network designers have migrated to 50um fiber,especially laser optimized multimode fibers (OM3), as they can support higher data rates and longer distances. Considering the higher bandwidth advantage, and the applications that most customers will use today or in the future, the Fiber Optics LAN Section recommends that for new installations, customers install OM3 fiber.

While 50um multimode fiber might seem new, in the 1970s, when optical fiber was introduced, standard 50um fiber (OM2) was the most popular of the early fiber types available, and was used for both long haul and short reach applications.

After the introduction of single-mode fiber in the 1980s for long haul telephony applications, multimode fibers were applied to short-reach interconnects, such as building and campus backbones needing support over distances from 300 meters to 2000 meters. As with many technology choices, there were trade offs between 50um multimode and the singlemode fiber systems. The light-emitting diode (LED) sources used for multimode applications had a very large "spot†and the 50um fiber did not fully couple the available power into the 50um core. Consequently, 50um fiber used with 850 nm wavelength LEDs was limited in distance. Receivers were not always able to detect an adequate light power at the distant end of the backbone. Still, network designers were reluctant to install single mode fibers as the power sources remained more expensive and there was no need in most premises applications for the long link lengths the more expensive singlemode facilities would provide.

62.5um multimode fiber (OM1) was introduced in 1985 to solve these two problems. Because more light from LEDs could be coupled into its larger core, OM1 fiber could support 2 km campuses at 10 Mb/s. At the same time, its higher numerical aperture, which can be thought of as the fiber’s "light gathering†ability, made it easier to cable. Through much of the 1980’s and 90’s one multimode fiber, 62.5um core FDDIfiber became a defacto standard among the vast majority of LAN installations. Despite continual upgrades in LAN bandwidth requirements, FDDI grade fiber remained a work horse for backbone fiber installations for many years, and is still present in legacy systems. Now we recommend you one type of multimode fiber patch cable from fiberstore.

Multimode fiber patch cables can be used as cross)connect jumpers, equipment and work area cords. All Signamax optical fiber patch cords are manufactured using riser) grade (OFNR) cable and are 100% factory tested for insertion and return loss to ensure transmission per formance perANSI/TIA)56![]() C.3 standard specifications.Patch cords terminated with ST,SC, LC and MT)RJ connectors (uniform and hybrid versions) are available in duplex and simplex designs. Our store have 2.5 mm st to lc and other types of fiber patch cords.

C.3 standard specifications.Patch cords terminated with ST,SC, LC and MT)RJ connectors (uniform and hybrid versions) are available in duplex and simplex designs. Our store have 2.5 mm st to lc and other types of fiber patch cords.

Fiberstore produces high quality Fiber Optic Patch Cable using a variety of commercially available connectors and fibers. These patchcords offer low insertion losses, and excellent repeatability. Patchcords can be manufactured to any specified length. An array of cable materials are available, including unjacketed fiber, 0.9 mm outside diameter (O.D) loose tube buffer, 3 mm O.D kevlar rein-forced PVC jacketing, 3 mm armored cabling, and 5 mm heavy duty armored cabling as well as 3 mm or 5 mm Stainless Steel armored cablings.

Article Source: http://www.fiber-optic-components.com/how-to-chosse-the-multimdoe-fiber-for-data-communications.html

Posted by: kelonlau at

08:29 AM

| No Comments

| Add Comment

Post contains 669 words, total size 5 kb.

December 12, 2014

Fiber optic patch cords are one of the simplest elements in any optical network, consisting of a piece of fiber optic cable with a connector on each end. Despite its simplicity, the Fiber Optic Patch Cord can have a strong effect on the overall performance of the network. The majority of problems in any network occur at the physical layer and many are related to the patch cord quality, reliability, and performance. Therefore, using patch cords that are more reliable helps reduce the chance of costly network downtime. This article mainy the patch cord reliability.

Network designers would prefer components with a history of proven long-term performance. However, since optical networking is a relatively new technology, there is no significant long-term data for many components. Therefore, designers must rely upon testing from the component manufacturer or supplier that can simulate this history and assure the quality and reliability over the life of the network. This paper discusses the importance of quality, reliability, and performance as they relate to industry standards and manufacturing practices. The performance of the patch cord is also studied using a "perfect patch cord†and polishing observations as tools to understand patch cord principles.

Patch cord reliability is guaranteed not only by using quality components and manufacturing processes and equipment, but also by adherence to a successful Quality Assurance program. While patch cords themselves are typically tested 100% for insertion loss and return loss, if applicable, there are many other factors that need to be monitored to insure the quality of the patch cord.

One of the most important factors is the epoxy. Epoxies typically have a limited shelf life and working life, or "pot life.†This information is readily available from the manufacturer. It is absolutely necessary that both of these criteria be verified and maintained during manufacture. Epoxy beyond its expiration date needs to be discarded. Chemical changes affecting the cured properties of the epoxy can occur after this date. This date can also be dependent on storage conditions, which need to be observed.

Most epoxies used in fiber optic terminations are two-part epoxies and, while they cure at elevated temperatures, preliminary cross-linking will begin upon mixing. Once this has started, the viscosity of the epoxy can begin to change, making application more difficult over time. The epoxy can become too thick to fill the ferrule properly and too viscous to enable a fiber to penetrate, causing fiber breakage.

Many of the tooling used in lc to st patch cable assembly also has periodic maintenance and a limited tool life. This includes all stripping, cleaving and crimping tools. Most stripping tools, whether they are hand tools or automated machines, can be damaged by the components of the cable, most notably the aramid yarn strength members. Buffer strippers will dull with prolonged usage, increasing the likelihood that they will not cleanly cut the buffer. This can lead to overstressing the fiber when the buffer is pulled off. When a cleaving tool wears out and a clean score is not made, it is almost impossible to detect during manufacturing. However, the result could be non-uniform fiber breakage during the cleave, which can result in either breaking or cracking the fiber below the ferrule endface. In this instance, the connector will have to be scrapped. Even crimp tools require periodic maintenance to insure the proper forces and dimensions are consistent. Crimp dies also have a tendency to accrue epoxy build-up, which can affect the crimping dimensions and potentially damage the connector.

The integrity of the incoming materials and manufacturing processes, once specified, needs to be adhered to all the appropriate guidelines and procedures. The importance of these materials not only has a strong influence on product reliability, but also on product performance.

Fiber optic patch cords are fiber optic cables used to attach one device to another for signal routing. It compresses in the entire electric network plank and room that wall plank and the flexibility cabinet needs, causes such the person who passes room merely considerably traditional FC,LC,ST and SC’s connection box in parts.Intelligently the bright and beautiful corporation adopts well-developed technique and installation, and carrying on scale manufacture, the produce performance is good, and the quality is steady dependable. Fiberstore manufactures fiber optic patch cables, fiber optic patch cords, and pigtails. There are LC, SC, ST, FC, E2000, SC/APC, E2000/APC, MU, VF45, MT-RJ, MPO/MTP, FC/APC, ST/APC, LC/APC, E2000, DIN, D4, SMA, Escon, FDDI, RoHS compliant, LSZH, Riser,Plenum, OFNR, OFNP, simplex, duplex, single mode, 9/125, SM, multimode, MM, 50/125, 62.5/125; armored fiber optic patch cords, OM4 patch cord, waterproof fiber optic patch cords, ribbon fiber optic cables and bunched fiber optic cables.

Article Source: http://www.cables-solutions.com/the-fiber-optic-patch-cord-reliability.html

Posted by: kelonlau at

07:46 AM

| No Comments

| Add Comment

Post contains 784 words, total size 6 kb.

December 11, 2014

The LC connectors used are small form-factor fiber optic connectors resembling miniature SC connectors with high quality 1.25mm zirconia ferrules and push-pull latching mechanism. They are fully compatible with existing LC hardware.

In addition to basic testing, some mechanical and environmental tests per IEC or Telcordia are also performed periodically to guarantee the best quality. For standard Fiber Optic Patch Cord, sampling check is performed on ferrule geometry to ensure high percentage of polished connectors meeting GR-326 requirements. For premium grade, ferrule geometry is tested on all patch cords to meet these GR-326 requirements. The following is LC to LC fiber patch cable, LC-LC fiber optic patch cables are used to send high-speed data transmissions throughout your network. LC/LC fiber optic cables connect two components with fiber optic connectors. A light signal is transmitted so there is no outside electrical interference.

Other than standard single mode and multimode fibers, G655, OM2, and OM3 fibers are also available upon request. Flame retardant grade cable sheathing options are offered. Riser rated cable will be provided as standard. LSZH and Plenum can be provided upon request.

The SC connectors used for our patch cords are designed to NTT-SC* standards and are fully compatible with existing SC hardware. Two simplex connectors can be configured into a duplex format by adding a duplex clip.

In addition to basic testing, some mechanical and environmental tests per IEC or Telcordia are also performed periodically to guarantee the best quality. For standard patch cords, sampling check is performed on ferrule geometry to ensure high percentage of polished connectors meeting GR-326 requirements. For premium grade, ferrule geometry is tested on all patch cords to meet these GR-326 requirements. The following is SC to SC fiber patch cable, SC to SC Fiber Optic jumper cords are primarily used in high bandwidth networks where you must send large amounts of data at high speeds. Use a SC to SC fiber jumper cable to connect two devices with SC connections. Since the data is sent via a light signal, there is no electrical interference. Multimode SC/SC fiber cables are used to send multiple light signals at a time throughout gigabit networks. They are usually used in shorter cable runs, and have inner core diameter of 62.5 micron. The 62.5um cables support distances to 275 meters.

Other than standard single mode and multimode fibers, G655, OM2, and OM3 fibers are also available upon request. Flame retardant grade cable sheathing options are offered. Riser rated cable will be provided as standard. LSZH and Plenum can be provided upon request.

Fiberstore offers the most complete selection and great quality fiber optic patch cables! We carry singlemode and multimode optical fiber patch cables with a variety of connector types such as LC, SC, ST, and MTRJ. Duplex fiber cables consist of two fiber cores and can be either multimode or singlemode.

Article Source: http://www.fiber-optic-components.com/fiberstore-lc-and-sc-fiber-optic-patch-cord.html

Posted by: kelonlau at

07:42 AM

| No Comments

| Add Comment

Post contains 486 words, total size 6 kb.

December 10, 2014

With improved efficiency and lower costs, optical swiching provides the key for carries to both manage the new capacity that dense wavelength division multiplexing (DWDM) provides and gain a competitive advantage in the recruitment and retention of new customers. However, with two types of optical swiches being offered, there is a dabate over which type of switch to deploy-intelligent, optical-electrical-optical (OEO) switches, or all-optical, optical-optical-optical (OOO) swiches. The real answer is that both switches offer distinct advantages and, by understanding where and when deployment makes sense, carriers can optimize their network and service offerings.

Carries have embraced DWDM as a mechanism to quickly respond to an increasing need for bandwidth, particularly in the long-haul core network. Many of these carries have also recognized that this wavelength-based infrastructure creates the foundation for the new-generation optic network. However, as DWDM delivers only raw capacity, carries now need to implement a solution to manage the bandwidth that DWDM provides. Optical switches advantage in the recruitment and retention of new customers. To secure improved efficiency, lower cost, and new revenue-generating services, carries have at least two choices of optical swiches to control their bandwidth and rising capital expenses (CAPEX), the OEOFiber Optical Switch and the all-optical, photonic-based OOO switch, which will be discussed in complete detail in Section 10.1.3. A logical evolution path to the next-generation network must include the deployment of intelligent OEO switches to ensure that current needs are met and all-optical OOO swiches are added where and when they make sense. Therefore, there is no debate on whether carries need to deploy either OEO or OOO, but there is debate on how to optimize network and service offerings through the implementation of both switch types.

In addition, recent economic challenges have highlighted the fact that the network evolution must increase the efficiency and manageability of a network, resulting in lower equimpment and operation costs. A growing number of carriers have accepted the evoloutionary benefits of the optical switch. Carries must decide how best to implement the optical swich to gain a competitive advantage in the recruitment and retention of new customers. Promises of improved efficency, lower cost, and new revenue-generating services are being made by manufactures of two types of optical switches-the OEO switch and the all-optical, photonic-based OOO switch.

Now the following we recommend you two optical swiches from Fiberstore, they are Optical Bypass Switch, 1×2 fiber optic switch.

The Dual 2×2 Bypass Opto-Mechanical Bi-directional Fiber Optic Switch connects optical channels by redirecting 4 incoming optical signals into 4 output fibers. This is achieved using a opto-mechanical configuration and activated via an electrical control signal. The Optical Bypass Switch has integrated electrical position sensors.Based on thin film filter technology that provides a robust method of altering the light patch, this series of products has a drastically simplified platform configuration offering high reliability and low production cost. This novel design significantly reduces moving part position sensitivity, offering unprecedented high stability as well as an unmatched low cost.

Features

Compact design, Miniature size

Short switching time

Bi-directional

Low optical distortions

Low cross talk, Low Insertion Loss

Wide operating wavelength Range

Seam-seal package

Highly Stable & Reliable

Epoxy-free on Optical Path

Single mode or Multimode optional

Fail-Safe Latching and Non-latching

The 1×2 fiber optic switch connects optical channels by redirecting 1 incoming optical signals into 2 output fibers. This is achieved using a opto-mechanical configuration and activated via an electrical control signal. The switch has integrated electrical position sensors.Based on thin film filter technology that provides a robust method of altering the light patch, this series of products has a drastically simplified platform configuration offering high reliability and low production cost. This novel design significantly reduces moving part position sensitivity, offering unprecedented high stability as well as an unmatched low cost.

Optical switch is a device that enables signals in optical fibers or integrated optical circuits to be selectively switched from one circuit to another. It is mainly used in optical add/drop, optical cross connection, and optical fiber ring protection. We supply optical switches based on Mechanical Optical Switch, MEMS Optical Switch, Solid-State technology with proven reliability and the configurations are available as 1 x 1, 1 x 2, 2 x 2, etc.. Moreover, we offer non-latching, latching, single-mode and multimode versions. Our optical switches are all with high quality and ready for the FTTx applications.

Article Source: http://www.cables-solutions.com/basics-of-optic-switching.html

Posted by: kelonlau at

04:23 AM

| No Comments

| Add Comment

Post contains 730 words, total size 7 kb.

December 03, 2014

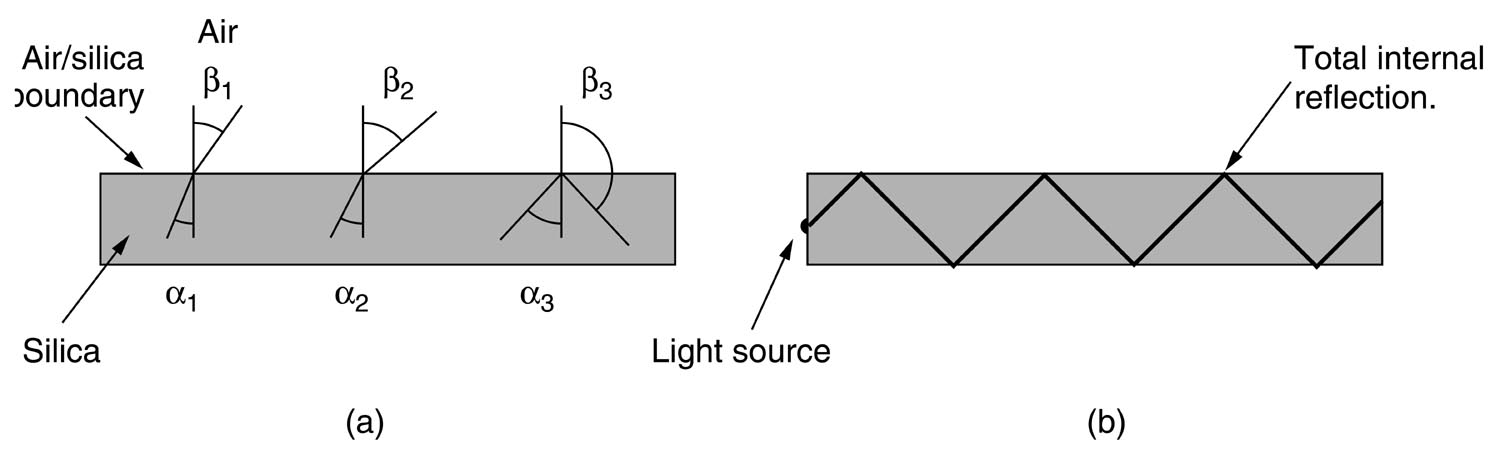

Figure 1.4 shows the principle of light propagation through a fiber optic cable. To understand the principle, consider when light is injected into an optical material that is surrounded by another optical material with a differnt index of refraction. The first and second optical materials will have a higher and lower index of refraction. The first and second optical materials will have a higher and lower index of refraction, respectively. Figure 1.4(a) shows light incident at an angleθto the normal. The light refracts by an angle βfrom the normal. If the angle of incidence is increased, the angle of refraction will also increase, as shown in Figure 1.4 (b). In Figure 1.4(c), light incident at an angleθequal to the critical angleθ gives an angle of refraction βof 90 degrees. The refracted light lies on the interface of the first-second optical materials. Snell’s Law is applicalbe here. In Figure 1.4(d), when light lands incident at an angle θ greater than the critical angle, the light will reflect by the total internal reflection phenomena. In this case, the angle of incidence equals the angle of reflection, which is defined by the first law of light.

Assume the first optical material is very long. It has a circular cross section with a very small diameter like the core, and at the same time is surrounded by another optical material resembling the cladding in a fiber optic cable, as shown in Figure 1.4(e). Now, light injected into a fiber optic cable and striking the core-to-cladding interface at a greater angle than the critical angle reflects back into the core. Since the angles of incidence and reflection are equal, the relected light will again be reflected. The light will continueto bounce through the length of the fiber cable. Light in Figure 1.4 Cases (a), (b), and (c) show that the light passes into the cladding. The cladding is usually inefficient as a light carrier compared to the core of Plastic Optical Fiber Cable. Light in the cladding becomes part of the losses, some of which will be presented in coming sections of the chapter, that usually occur in any fiber optic cable. Therefore, light propagation in a fiber optic cable is governed by the following:

â— The wavelength of light

â— The angle of incidence of the light at the input of the fiber cable

â— The indices of refraction of the core and cladding

â— The composition of the core and cladding

â— The length of the cable

â— The bending radius of the cable

â— The sizes of the core and cladding

â— The design of the core and cladding

â— The transmission modes

â— The temperature and environment conditions of the fiber cable

â— The strength and flexibility of the fiber cable

Fiberstore provides affordable high quality cables and accessories to our customers, primarily focusing on the needs of the Fiber optic networks installers, and resellers of fiber optic products. All products can be custom fiber optic manufactured and guaranteed. Our fiber optic cable products have high degree of flexibility and customization. Buy Bulk Fiber Optic Cable from us, we can ensure you receive a product designed for your specific need and application, from straightforward simplex patch cords to custom optical sub-assemblies. We also provide fiber optic solution for customer, provide various and one-step fiber optic solutions to carriers and end-users with in-depth knowledge and overall consideration.

Posted by: kelonlau at

06:18 AM

| No Comments

| Add Comment

Post contains 571 words, total size 5 kb.

35 queries taking 0.1516 seconds, 110 records returned.

Powered by Minx 1.1.6c-pink.