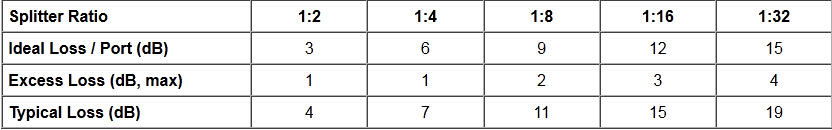

Fiber optic splitter, also named beam splitter, is based on a quartz substrate of integrated waveguide optical power distribution device, the same as coaxial cable transmission system, The optical network system also needs to be an optical signal coupled to the branch distribution, which requires thepassive optical splitter, Is one of the most important passive devices in the optical fiber link, is optical fiber tandem device with many input terminals and many output terminals, Especially applicable to a passive optical network (EPON, GPON, BPON, FTTX, FTTH etc.) to connect the MDF and the terminal equipment and to achieve the branching of the optical signal.

Fiber optic splitter is a key optical device in passive optical network (PON) systems, also known as a passive optical splitter, which splits the optical signal power evenly into all the output ports. In the PON field plant, a1x8 splitterto 1 × 32 splitter is placed on an electric pole, connecting the distribution optical cable in the air and the drop wire to the customer premises. A 1 × N splitter can be part of an N × N star coupler.

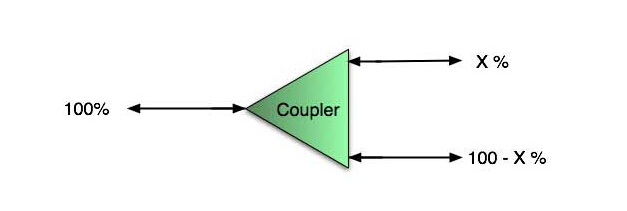

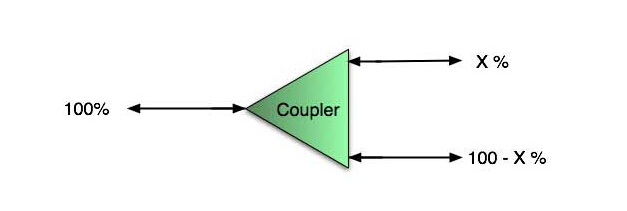

A fiber optic splitter is a device that splits the fiber optic light into several parts by a certain ratio. For example, when a beam of fiber optic light transmitted from a 1X4 equal ratio splitter, it will be divided into 4-fiber optic light by equal ratio that is each beam is 1/4 or 25% of the original source one. A fiber optic splitter is different from WDM. WDM can divide the different wavelength fiber optic light into different channels. fiber optic splitter divide the light power and send it to different channels.

Most Splitters available in 900μm loose tube and 250μm bare fiber. 1x2 and 2x2 couplers come standard with a protective metal sleeve to cover the split. Higher output counts are built with a box to protect the splitting components

Fiberstore stocks hundreds of fiber optic adapter, fiber coupler, and fiber optic splitter solutions for both Multimode and Single mode fiber applications. We offer ST, SC, FC, LC, MTRJ, and MU style fiber optic adapters and fiber coupler products for just about every fiber cabling design requirement.

1

Touche. Great arguments. Keep up the great spirit.

Posted by: personal injury auto accident at June 25, 2015 01:22 AM (wlZo1)

2

I don't even know how I ended up here, but I thought this post was good.

I don't know who you are but certainly you are going to a famous blogger if

you are not already

Cheers!

Posted by: his comment is here at June 25, 2015 06:16 PM (ZEs4U)

3

Great blog right here! Additionally your site quite a bit up very fast!

What host are you the use of? Can I am getting your associate link for your host?

I wish my website loaded up as fast as yours lol

Posted by: kamagra tabletki na potencje at July 12, 2015 05:20 AM (Q9TRP)

4

Weed is demonstrated to have several medical uses which might be much better than most prescription medication.

Posted by: Lettie at July 13, 2015 08:38 AM (RSnuI)

5

The pricing for a hosting environment can be massively

different for different solutions and also the level of the company.

In general, you can expect to pay $ 50-10 per month, shared web hosting services.

This could pose both a physical and moral

problem for the owners of the children's website.

Don't forget that should you need more of 'whatever

they are offering' you can upgrade at a later stage; it

is a tad more difficult to downgrade. Finally the decision resides with you and your needs for

making the choice. If you wish to save some cash, shared hosting will be the best option for you.

With dedicated software, you can be assured that your website and server won't be attached by viruses and malware.

Going for a VPS hosting plan from the existing shared hosting plan. Dedicated servers ensure that no bandwidth, hard drive space, memory or anything else related to your website hosting

is shared with anyone else. Since there are not

many resources to create advanced websites with a free hosting service, it's best for personal sites, such as those for family or hobbies.

Posted by: Hostgator 1 Cent Coupon at July 13, 2015 10:41 AM (QPCwQ)

6

Whenever we look straight back during the organizations that

were taken to existence whenever you want over the last ten years, hardly any had a pre-defined Search Engine Optimization plan.

Posted by: Lance at July 13, 2015 12:16 PM (GndtI)

7

When you share a computer with several other websites you

are basically sharing the same system resources so if the machine only has 1 GB

of RAM if you install a script which uses

500 MB of RAM the other 50 sites which might be

sharing the same environment will be affected because your site is already consuming

half of the system resources. Unlike phone video conferencing more options for interaction between the presenter and the participants are available.

If you are planning to move from a shared to a dedicated hosting environment without having

to incur significant rise of costs, the logical step is to move to VPS hosting server first.

A fast approach to crop an image is to zoom in on the image how you would like

it cropped and take a screen shot of the zoomed in image.

Because of the scalable feature the required amount of space on these web hosting servers can be increased in accordance

with the requirements of the users. You have a place where you can test your web

projects, a place to store all the multimedia files that are played at network-enabled players in your home, and a separate machine to run a

torrent client. As technology progresses, so is the way how people makes transactions and

do business. However, the case is bit different with shared

hosting account. You as a user have multiple options in the market of cheap web

hosting to choose; you can settle for a greater tradeoff in addition to very cheap web

hosting service. Depending on the level of downloading you may chose a best web hosting server.

Posted by: Hostgator Coupon Code at July 13, 2015 12:24 PM (ghZoi)

8

Never rely on the application's built-in article builder and spinner (you

can use these for the tier 2 links, where quality is not an important factor).

Posted by: Magic Submitter Reviews at July 13, 2015 01:35 PM (ghZoi)

9

Pages designed to rank in serach engines for highly targeted search questions, typically designed to redirect searchers to

a typical page along with other ads.

Posted by: Celsa at July 13, 2015 02:48 PM (QPCwQ)

10

Particularly the CSS one, I'd no concept about this!!

Posted by: Claribel at July 13, 2015 03:17 PM (OFtUI)

11

Therefore, many thanks for sharing your knowledge!

Posted by: Etta at July 13, 2015 05:34 PM (cTHpi)

12

Proper underwriting of equipment becomes necessary.

Posted by: Mary at July 13, 2015 05:51 PM (virfp)

13

Relying upon your web application, the server can also require the following:

. Not to be brushed under the rug, there are also semi-dedicated and business hosting options, but those often still offer the same as a shared hosting plan, only with more space.

The host implements research team has been beneficial, economical and

beneficial to al the players in the industry today.

A fast approach to crop an image is to zoom in on the image how you would like it cropped and

take a screen shot of the zoomed in image. A dedicated hosting service, dedicated

server, or managed hosting service is a type of Internet hosting in which the client leases an entire server not shared with anyone

else. This has been brought about by the need to revolutionize and make

the internet experience one of the most entertaining and rewarding as possible.

For most of us who are trying to create and launch our own websites for the

first time, it can be a daunting task in many ways.

You enter an IP or DNS name and start and stop a port range, and this tool

will be a port scan shows all open ports. A server is a computing device

that manages the resources of a computer network.

Since there are not many resources to create advanced websites with a

free hosting service, it's best for personal sites, such as those for family or hobbies.

Posted by: Hostgator 1 Cent Coupon at July 13, 2015 06:36 PM (KZ722)

14

It is obvious that you need to check out the Website

requirements, then decide whether you require virtual private server hosting

or any other type of hosting service. Cutting-Edge Tools:

Certified Partners Get Exclusive Tools One of the major benefits of being a Microsoft Gold Partner is access to the latest Microsoft

tools and technologies. Market reports suggest that more than 90% of the

website hosted on the Internet do not receive great amount of traffic,

which implies that shared hosting can cater to the hosting needs of more than 90%

of the web owners out there in the online marketplace without creating a hole in their wallet.

Many of today's web hosts offer up affordable and reliable website hosting for only a few dollars a

month in some cases. While some of them are relatively simple and inexpensive, others

are of a greater complexity. Typically, shared hosting plans start at $5 - $20 per month.

For most of us who are trying to create and launch our own websites for the first time,

it can be a daunting task in many ways. Because of this, the demand

VPS hosting in India has increased considerably in the past

few years. Now website is more complex, contains CSS,

databases and scripting language. Small companies and individuals with small sites are probably better off with shared hosting.

Posted by: Hostgator Coupons July at July 14, 2015 12:01 AM (IMdx5)

15

Sweet blog! I found it while browsing on Yahoo News.

Do you have any suggestions on how to get listed in Yahoo News?

I've been trying for a while but I never seem to get there!

Cheers

Posted by: norsk spill at July 14, 2015 11:46 AM (oZwtu)

16

I was pretty pleased to uncover this page. I nee to to thank you for your time due to this fantastic read!!

I definitely liked every bit of itt aand I have you book marked to check out

neew information in your website.

Posted by: Acai-Beere Präparate at July 16, 2015 04:44 AM (LZ/xA)

17

The physical comfort of workers has a lot of influence on their

state of mind. Purchase these office items from suppliers that offer them

with low amounts of emission, since these levels do affect the quality of indoor air.

) There are also remnants from my sister's wedding presents,

from a time when giving mundane presents like pots and pans

was acceptable, along with an assortment of non-stick, easy

clean pans in various sizes.

Posted by: Shoes Cabinet at July 16, 2015 10:14 AM (nQY+c)

18

This is my first time visit at here and i am truly impressed to read all at single place.

Posted by: http://www.impera.mx at July 16, 2015 10:44 AM (8HIw+)

19

Hi to every body, it's my first pay a quick visit of this blog; this

blog includes remarkable and in fact good material for visitors.

Posted by: http://vai.la/ at July 16, 2015 11:20 AM (4KHTk)

20

He then buys 10 binary options from a binary choicss broker worth $one

hundred each just before the offered deadline.

Posted by: binary options strategy at July 16, 2015 05:20 PM (P2H7v)

21

wonderful video telling the truth, I did nnot require to acquire thhe

plan to know it is a scam, i use -flow ffor day-to-day revenue.

Posted by: binary options brokers us at July 16, 2015 07:21 PM (5rt1V)

22

Everything is very open with a clear clarification of the issues.

It was definitely informative. Yoour site is very helpful.

Thank you for sharing!

Posted by: http://eshops.primeapps.gr/component/k2/author/39935 at July 16, 2015 07:47 PM (gnedq)

23

Through the use of this website, you agree to the Terms of Use and Privateness Coverage Wikipedia® is a registered trademark of the Wikimedia Basis, Inc.

Posted by: ted 2 cały film at July 17, 2015 03:13 AM (SsCsX)

24

It's an awesome paragraph for all the online people;

they will get advanntage from it I am sure.

Posted by: 1Blitzbrigadehack1.Wordpress.Com at July 17, 2015 11:32 AM (zdnge)

25

My spouse and I stumbled over here different web page and thought I may as well

check things out. I like what I see so now i am following you.

Look forward to finding out about your web page repeatedly.

Posted by: tips for travelling to europe at July 17, 2015 11:54 AM (uAK8Q)

26

Place the alarms in areas frequented by workers, such as offices, break rooms,

hallways, appliance rooms and other work areas. I also emphasized on one

of its benefit concerning indoor heat reduction of your home.

In older properties there have ben countless cases of tenants actually removing the batteries from detectors because

of annoying warning beeps when the battery is wearing out.

Posted by: alarm Hua Hin at July 17, 2015 02:05 PM (XNwX+)

27

Modern vehicles are complex machines which are engineered and mass produced

for the purpose intended, as designed. Then, you will need to drill some holes, and install some brackets.

It is critical that you home contain a home alarm and monitoring system.

Posted by: alarm Hua Hin at July 17, 2015 06:14 PM (XNwX+)

28

Skoro wiem, że woli kalsze w gwiazdki od tych

w kwiaty, to mogę ama szybko je kupić po pracy.

Posted by: Lindsey at July 18, 2015 10:15 AM (TBQq5)

29

Hurrah, that's what I was looking for, what a stuff! existing here at this web site, thanks admin of this website.

Posted by: ac repair st louis mo at July 18, 2015 12:04 PM (zDJOf)

30

I've been surfing online more than three hours today,

yet I never found any interesting article like yours.

It's pretty worth enough for me. In my opinion, if all web owners and

bloggers made good content as you did, the net will be much more useful than ever before.|

I could not resist commenting. Perfectly written!|

I'll immediately grasp your rss as I can not find your

email subscription hyperlink or e-newsletter service.

Do you have any? Kindly allow me know so that I may subscribe.

Thanks.|

It's perfect time to make some plans for the future and it's time to be happy.

I've read this post and if I could I wish to suggest you few interesting things or tips.

Perhaps you can write next articles referring to this article.

I want to read more things about it!|

It's appropriate time to make some plans for the longer term and it

is time to be happy. I've learn this post and if I may I want to counsel

you some fascinating issues or suggestions. Maybe you could write next articles

referring to this article. I want to learn more issues approximately it!|

I have been surfing on-line greater than 3 hours

as of late, but I never found any fascinating article like yours.

It is pretty worth sufficient for me. In my opinion, if all website owners and bloggers made excellent content as you did, the net will be a lot more helpful than ever before.|

Ahaa, its good discussion on the topic of this post

here at this web site, I have read all that, so

now me also commenting here.|

I am sure this article has touched all the internet users, its really really pleasant article on building up new weblog.|

Wow, this post is nice, my younger sister is analyzing these kinds of things, so I am

going to inform her.|

bookmarked!!, I love your blog!|

Way cool! Some extremely valid points! I appreciate you penning

this write-up plus the rest of the website is also really good.|

Hi, I do believe this is a great blog. I stumbledupon it

I'm

going to come back once again since I book marked it. Money and

freedom is the best way to change, may you be rich and continue to help

others.|

Woah! I'm really enjoying the template/theme of this blog.

It's simple, yet effective. A lot of times it's challenging to get that "perfect balance" between usability and visual appearance.

I must say you've done a fantastic job with this. Also,

the blog loads very fast for me on Safari. Exceptional Blog!|

These are truly wonderful ideas in regarding blogging.

You have touched some good things here. Any way keep up wrinting.|

I enjoy what you guys are usually up too. Such

clever work and exposure! Keep up the excellent works guys I've included you guys to my personal blogroll.|

Hey! Someone in my Myspace group shared this site with us so I came

to give it a look. I'm definitely enjoying the information. I'm

book-marking and will be tweeting this to my followers! Terrific blog and great design.|

I like what you guys are usually up too. This type of clever work and

coverage! Keep up the amazing works guys I've included you guys to my personal blogroll.|

Hi there would you mind sharing which blog platform you're working with?

I'm looking to start my own blog soon but I'm having a difficult time making a decision between BlogEngine/Wordpress/B2evolution and Drupal.

The reason I ask is because your design seems different then most blogs and I'm looking for something completely unique.

P.S Apologies for being off-topic but I had to ask!|

Hi would you mind letting me know which webhost

you're using? I've loaded your blog in 3 different internet browsers and

I must say this blog loads a lot faster then most.

Can you recommend a good web hosting provider at a

reasonable price? Many thanks, I appreciate it!|

Everyone loves it whenever people get together and share thoughts.

Great blog, stick with it!|

Thank you for the good writeup. It in fact was a amusement account it.

Look advanced to far added agreeable from you!

However, how could we communicate?|

Hey there just wanted to give you a quick heads up. The words in your content seem

to be running off the screen in Safari. I'm not sure if this is a formatting issue or something to do with browser compatibility but I thought I'd post to let

you know. The layout look great though! Hope you get the problem fixed soon. Kudos|

This is a topic which is near to my heart... Many thanks!

Exactly where are your contact details though?|

It's very effortless to find out any matter on net as compared to textbooks, as I found this article

at this web page.|

Does your blog have a contact page? I'm having problems locating it but, I'd like

to send you an email. I've got some ideas for your blog you might be interested

in hearing. Either way, great blog and I look forward to seeing it expand over time.|

Hello! I've been following your blog for a while now and finally got the courage

to go ahead and give you a shout out from Atascocita Tx!

Just wanted to mention keep up the excellent

work!|

Greetings from Los angeles! I'm bored to death at work so I decided

to check out your website on my iphone during

lunch break. I enjoy the information you present here and can't wait

to take a look when I get home. I'm shocked at how quick your

blog loaded on my mobile .. I'm not even using WIFI, just 3G ..

Anyways, superb site!|

Its like you read my thoughts! You appear to understand so much about this, like you wrote the guide

in it or something. I believe that you just could do with some p.c.

to power the message home a bit, however instead of that, this is great blog.

A fantastic read. I will certainly be back.|

I visited various web sites except the audio quality for audio songs current at this

web page is in fact wonderful.|

Hi, i read your blog from time to time and i own a similar one and i

was just wondering if you get a lot of spam

remarks? If so how do you prevent it, any plugin or anything you can advise?

I get so much lately it's driving me crazy so any assistance is very much appreciated.|

Greetings! Very helpful advice in this particular

post! It's the little changes that make the most important changes.

Many thanks for sharing!|

I seriously love your blog.. Great colors & theme.

Did you create this amazing site yourself? Please reply

back as I'm planning to create my own blog and would love to find out where you got this from or just what the theme is called.

Cheers!|

Hello there! This article couldn't be written any better!

Looking through this post reminds me of my previous roommate!

He continually kept preaching about this. I'll forward this post to

him. Fairly certain he'll have a great read. Thanks for sharing!|

Amazing! This blog looks exactly like my old one! It's on a entirely different topic but it has

pretty much the same page layout and design. Excellent choice of colors!|

There is certainly a lot to learn about this topic.

I really like all of the points you made.|

You've made some decent points there. I looked on the web to learn more about the issue and found most individuals will go along with your views on this web site.|

What's up, I log on to your blogs daily. Your humoristic

style is witty, keep doing what you're doing!|

I simply could not leave your website before suggesting that I really enjoyed the standard info an individual supply for your guests?

Is going to be again ceaselessly to check out

new posts|

I need to to thank you for this good read!!

I definitely loved every bit of it. I have got you book-marked to look

at new things you post…|

Hi, just wanted to tell you, I liked this article. It was helpful.

Keep on posting!|

Hello, I enjoy reading through your article post. I wanted to

write a little comment to support you.|

I every time spent my half an hour to read this blog's articles all the time along with a cup of coffee.|

I all the time emailed this website post page to all my associates, for the reason that

if like to read it then my links will too.|

My developer is trying to persuade me to move to .net from PHP.

I have always disliked the idea because of the costs.

But he's tryiong none the less. I've been using WordPress on a number of

websites for about a year and am worried about switching to another platform.

I have heard good things about blogengine.net.

Is there a way I can import all my wordpress content into it?

Any kind of help would be greatly appreciated!|

Hi! I could have sworn I've been to this website before but after looking at many of the posts I realized it's new to me.

Regardless, I'm certainly delighted I stumbled upon it and I'll be book-marking

it and checking back regularly!|

Terrific work! This is the type of information that are supposed to be shared across the web.

Shame on Google for not positioning this put up higher!

Come on over and visit my site . Thanks =)|

Heya i'm for the first time here. I found this board and I find It really useful

& it helped me out much. I hope to give something back

and help others like you helped me.|

Hi, I do believe your site might be having browser compatibility problems.

Whenever I take a look at your website in Safari, it looks fine however when opening in IE, it has

some overlapping issues. I simply wanted to provide you

with a quick heads up! Aside from that, wonderful blog!|

Somebody essentially help to make significantly articles I would state.

This is the first time I frequented your website page and to

this point? I surprised with the analysis you made to create this particular put up extraordinary.

Fantastic job!|

Heya i'm for the primary time here. I found this board and I find It really helpful & it

helped me out much. I'm hoping to present something

back and aid others such as you helped me.|

Hello there! I simply want to offer you a big thumbs up for the great info you have got right here on this post.

I will be returning to your web site for more soon.|

I all the time used to study piece of writing in news papers but now as I am a user of web therefore from now

I am using net for content, thanks to web.|

Your mode of explaining the whole thing in this post is genuinely good,

all can effortlessly know it, Thanks a lot.|

Hello there, I discovered your site by means of Google even as searching for a similar

subject, your web site came up, it appears great.

I've bookmarked it in my google bookmarks.

Hello there, simply become aware of your weblog through Google, and found that it's truly informative.

I'm gonna watch out for brussels. I will be grateful in case you continue this in future.

A lot of other folks might be benefited out of your writing.

Cheers!|

I'm curious to find out what blog system you are using? I'm having some

minor security problems with my latest website and I'd like to find something more risk-free.

Do you have any recommendations?|

I'm really impressed with your writing skills as well

as with the layout on your weblog. Is this a paid theme or did you modify it yourself?

Anyway keep up the nice quality writing, it

is rare to see a great blog like this one nowadays.|

I am extremely impressed along with your writing skills and also with the structure for your

weblog. Is this a paid topic or did you modify it yourself?

Anyway keep up the excellent high quality writing, it is rare

to peer a great blog like this one nowadays..|

Hello, Neat post. There is a problem along with your web site in web explorer, could test this?

IE nonetheless is the marketplace chief and a large element

of people will leave out your great writing because of this problem.|

I am not sure where you're getting your information, but great topic.

I needs to spend some time learning more or understanding more.

Thanks for great information I was looking for this info for my mission.|

Hello, i think that i saw you visited my site

so i came to “return the favorâ€.I am attempting to find things

to enhance my web site!I suppose its ok to use a few of your ide\

Posted by: louis vuitton bags uk at July 18, 2015 12:25 PM (O/xQ3)

31

Greetings from Ohio! I'm bored to tears at work so I decided to browse your website on my iphone during lunch break.

I really like the info you present here and can't wait to take

a look when I get home. I'm amazed at how fast your blog loaded on my phone ..

I'm not even using WIFI, just 3G .. Anyways,

good blog!

Posted by: Diabetes Destroyer Review at July 19, 2015 05:37 PM (O6nzQ)

32

As you see, no matter whether marketplace costs are going up or down, there is

propfit to be produced with binaryy possibilities trading.

Posted by: binary options robot at July 20, 2015 03:42 PM (kwbt/)

33

Please let me know if you're looking for a writer for your weblog.

You have some really great posts and I believe I would be

a good asset. If you ever want to take some of the load off, I'd love to write some content for your blog in exchange for a link back to mine.

Please blast me an email if interested. Many thanks!

Posted by: Online Success Plan System at July 21, 2015 06:55 PM (a4f/C)

34

{

{I have|I've} been {surfing|browsing} online more than {three|3|2|4} hours today, yet I never found

any interesting article like yours. {It's|It is} pretty worth enough for me.

{In my opinion|Personally|In my view}, if all {webmasters|site

owners|website owners|web owners} and bloggers

made good content as you did, the {internet|net|web} will be {much more|a lot more} useful than ever before.|

I {couldn't|could not} {resist|refrain from} commenting.

{Very well|Perfectly|Well|Exceptionally well} written!|

{I will|I'll} {right away|immediately} {take hold of|grab|clutch|grasp|seize|snatch} your {rss|rss feed} as I {can not|can't} {in finding|find|to find} your {email|e-mail} subscription {link|hyperlink}

or {newsletter|e-newsletter} service. Do {you have|you've} any?

{Please|Kindly} {allow|permit|let} me {realize|recognize|understand|recognise|know}

{so that|in order that} I {may just|may|could} subscribe.

Thanks.|

{It is|It's} {appropriate|perfect|the best} time to make some plans for the future and

{it is|it's} time to be happy. {I have|I've} read this post

and if I could I {want to|wish to|desire to} suggest

you {few|some} interesting things or {advice|suggestions|tips}.

{Perhaps|Maybe} you {could|can} write next articles referring to this article.

I {want to|wish to|desire to} read {more|even more} things about

it!|

{It is|It's} {appropriate|perfect|the best} time to make {a few|some} plans for {the future|the longer term|the long run} and {it is|it's} time to be happy.

{I have|I've} {read|learn} this {post|submit|publish|put up} and if I

{may just|may|could} I {want to|wish to|desire to}

{suggest|recommend|counsel} you {few|some} {interesting|fascinating|attention-grabbing} {things|issues} or {advice|suggestions|tips}.

{Perhaps|Maybe} you {could|can} write {next|subsequent} articles {relating to|referring to|regarding} this article.

I {want to|wish to|desire to} {read|learn} {more|even more}

{things|issues} {approximately|about} it!|

{I have|I've} been {surfing|browsing} {online|on-line} {more than|greater than} {three|3}

hours {these days|nowadays|today|lately|as of late}, {yet|but} I {never|by no means} {found|discovered}

any {interesting|fascinating|attention-grabbing} article like

yours. {It's|It is} {lovely|pretty|beautiful}

{worth|value|price} {enough|sufficient} for me. {In my opinion|Personally|In my view}, if all {webmasters|site owners|website owners|web owners} and

bloggers made {just right|good|excellent} {content|content material} as {you did|you probably did}, the {internet|net|web} {will be|shall be|might be|will probably be|can be|will likely be} {much more|a

lot more} {useful|helpful} than ever before.|

Ahaa, its {nice|pleasant|good|fastidious} {discussion|conversation|dialogue} {regarding|concerning|about|on the topic of} this {article|post|piece of writing|paragraph} {here|at

this place} at this {blog|weblog|webpage|website|web site},

I have read all that, so {now|at this time} me also commenting {here|at this place}.|

I am sure this {article|post|piece of writing|paragraph} has touched all the internet {users|people|viewers|visitors}, its really really {nice|pleasant|good|fastidious}

{article|post|piece of writing|paragraph} on building up new {blog|weblog|webpage|website|web site}.|

Wow, this {article|post|piece of writing|paragraph} is {nice|pleasant|good|fastidious},

my {sister|younger sister} is analyzing {such|these|these kinds of} things, {so|thus|therefore}

I am going to {tell|inform|let know|convey} her.|

{Saved as a favorite|bookmarked!!}, {I really like|I like|I love} {your blog|your site|your web site|your website}!|

Way cool! Some {very|extremely} valid points! I appreciate you {writing this|penning this} {article|post|write-up} {and the|and

also the|plus the} rest of the {site is|website is} {also very|extremely|very|also really|really} good.|

Hi, {I do believe|I do think} {this is an excellent|this is

a great} {blog|website|web site|site}. I stumbledupon it

{I will|I am

going to|I'm going to|I may} {come back|return|revisit} {once again|yet again} {since I|since i have} {bookmarked|book marked|book-marked|saved as a favorite} it.

Money and freedom {is the best|is the greatest} way to change, may you be rich and continue to {help|guide} {other

people|others}.|

Woah! I'm really {loving|enjoying|digging} the template/theme of this {site|website|blog}.

It's simple, yet effective. A lot of times it's {very hard|very

difficult|challenging|tough|difficult|hard} to get that "perfect balance" between {superb usability|user friendliness|usability} and {visual appearance|visual appeal|appearance}.

I must say {that you've|you have|you've} done a {awesome|amazing|very good|superb|fantastic|excellent|great} job with

this. {In addition|Additionally|Also}, the blog loads {very|extremely|super} {fast|quick} for me on {Safari|Internet explorer|Chrome|Opera|Firefox}.

{Superb|Exceptional|Outstanding|Excellent} Blog!|

These are {really|actually|in fact|truly|genuinely} {great|enormous|impressive|wonderful|fantastic} ideas

in {regarding|concerning|about|on the topic of} blogging.

You have touched some {nice|pleasant|good|fastidious} {points|factors|things} here.

Any way keep up wrinting.|

{I love|I really like|I enjoy|I like|Everyone loves} what you guys {are|are usually|tend to be} up too.

{This sort of|This type of|Such|This kind of} clever work and {exposure|coverage|reporting}!

Keep up the {superb|terrific|very good|great|good|awesome|fantastic|excellent|amazing|wonderful} works guys I've {incorporated||added|included} you guys to {|my|our||my

personal|my own} blogroll.|

{Howdy|Hi there|Hey there|Hi|Hello|Hey}! Someone in my {Myspace|Facebook} group shared this

{site|website} with us so I came to {give it a look|look it

over|take a look|check it out}. I'm definitely {enjoying|loving} the information. I'm {book-marking|bookmarking} and will be tweeting

this to my followers! {Terrific|Wonderful|Great|Fantastic|Outstanding|Exceptional|Superb|Excellent} blog and {wonderful|terrific|brilliant|amazing|great|excellent|fantastic|outstanding|superb}

{style and design|design and style|design}.|

{I love|I really like|I enjoy|I like|Everyone loves} what you guys {are|are usually|tend to be} up

too. {This sort of|This type of|Such|This kind of} clever work and {exposure|coverage|reporting}!

Keep up the {superb|terrific|very good|great|good|awesome|fantastic|excellent|amazing|wonderful} works guys I've {incorporated|added|included} you guys to {|my|our|my

personal|my own} blogroll.|

{Howdy|Hi there|Hey there|Hi|Hello|Hey} would you mind {stating|sharing} which blog platform you're {working with|using}?

I'm {looking|planning|going} to start my own blog {in the near

future|soon} but I'm having a {tough|difficult|hard} time {making a decision|selecting|choosing|deciding} between BlogEngine/Wordpress/B2evolution and Drupal.

The reason I ask is because your {design and style|design|layout} seems different

then most blogs and I'm looking for something {completely unique|unique}.

P.S {My apologies|Apologies|Sorry} for {getting|being} off-topic but I

had to ask!|

{Howdy|Hi there|Hi|Hey there|Hello|Hey} would you mind letting me know which {webhost|hosting company|web host} you're {utilizing|working with|using}?

I've loaded your blog in 3 {completely different|different} {internet browsers|web browsers|browsers} and I must

say this blog loads a lot {quicker|faster} then most. Can you {suggest|recommend} a good {internet hosting|web hosting|hosting} provider at a {honest|reasonable|fair} price?

{Thanks a lot|Kudos|Cheers|Thank you|Many thanks|Thanks}, I appreciate

it!|

{I love|I really like|I like|Everyone loves} it {when people|when individuals|when folks|whenever people} {come together|get together} and share {opinions|thoughts|views|ideas}.

Great {blog|website|site}, {keep it up|continue the good work|stick with it}!|

Thank you for the {auspicious|good} writeup. It in fact was

a amusement account it. Look advanced to {far|more} added agreeable from you!

{By the way|However}, how {can|could} we communicate?|

{Howdy|Hi there|Hey there|Hello|Hey} just wanted to give you a

quick heads up. The {text|words} in your {content|post|article} seem

to be running off the screen in {Ie|Internet explorer|Chrome|Firefox|Safari|Opera}.

I'm not sure if this is a {format|formatting} issue or something to do with

{web browser|internet browser|browser} compatibility but

I {thought|figured} I'd post to let you know. The {style and design|design and

style|layout|design} look great though! Hope you get the {problem|issue} {solved|resolved|fixed}

soon. {Kudos|Cheers|Many thanks|Thanks}|

This is a topic {that is|that's|which is} {close to|near to} my heart...

{Cheers|Many thanks|Best wishes|Take care|Thank you}!

{Where|Exactly where} are your contact details

though?|

It's very {easy|simple|trouble-free|straightforward|effortless} to find out any {topic|matter} on {net|web} as compared to {books|textbooks}, as I found this {article|post|piece of writing|paragraph} at this {website|web site|site|web

page}.|

Does your {site|website|blog} have a contact page?

I'm having {a tough time|problems|trouble} locating

it but, I'd like to {send|shoot} you an {e-mail|email}.

I've got some {creative ideas|recommendations|suggestions|ideas}

for your blog you might be interested in hearing. Either way, great {site|website|blog} and I look forward to seeing it {develop|improve|expand|grow}

over time.|

{Hola|Hey there|Hi|Hello|Greetings}! I've been {following|reading}

your {site|web site|website|weblog|blog} for {a long time|a while|some time} now and finally got the {bravery|courage} to go

ahead and give you a shout out from {New Caney|Kingwood|Huffman|Porter|Houston|Dallas|Austin|Lubbock|Humble|Atascocita} {Tx|Texas}!

Just wanted to {tell you|mention|say} keep up the {fantastic|excellent|great|good} {job|work}!|

Greetings from {Idaho|Carolina|Ohio|Colorado|Florida|Los angeles|California}!

I'm {bored to tears|bored to death|bored} at work so I decided to {check out|browse} your {site|website|blog} on my iphone during lunch

break. I {enjoy|really like|love} the {knowledge|info|information} you {present|provide} here and

can't wait to take a look when I get home. I'm {shocked|amazed|surprised} at

how {quick|fast} your blog loaded on my {mobile|cell phone|phone} ..

I'm not even using WIFI, just 3G .. {Anyhow|Anyways}, {awesome|amazing|very good|superb|good|wonderful|fantastic|excellent|great} {site|blog}!|

Its {like you|such as you} {read|learn} my {mind|thoughts}!

You {seem|appear} {to understand|to know|to

grasp} {so much|a lot} {approximately|about} this,

{like you|such as you} wrote the {book|e-book|guide|ebook|e book} in it or something.

{I think|I feel|I believe} {that you|that you simply|that you just} {could|can} do with {some|a few} {%|p.c.|percent} to {force|pressure|drive|power} the message {house|home} {a

bit|a little bit}, {however|but} {other than|instead of} that, {this is|that is} {great|wonderful|fantastic|magnificent|excellent}

blog. {A great|An excellent|A fantastic} read.

{I'll|I will} {definitely|certainly} be back.|

I visited {multiple|many|several|various} {websites|sites|web sites|web

pages|blogs} {but|except|however} the audio {quality|feature} for audio songs {current|present|existing} at this {website|web site|site|web page} is {really|actually|in fact|truly|genuinely} {marvelous|wonderful|excellent|fabulous|superb}.|

{Howdy|Hi there|Hi|Hello}, i read your blog {occasionally|from time to time} and i own a

similar one and i was just {wondering|curious} if you get a lot of spam {comments|responses|feedback|remarks}?

If so how do you {prevent|reduce|stop|protect against} it, any

plugin or anything you can {advise|suggest|recommend}?

I get so much lately it's driving me {mad|insane|crazy}

so any {assistance|help|support} is very much appreciated.|

Greetings! {Very helpful|Very useful} advice {within this|in this particular} {article|post}!

{It is the|It's the} little changes {that make|which will make|that produce|that will make}

{the biggest|the largest|the greatest|the most important|the most significant} changes.

{Thanks a lot|Thanks|Many thanks} for sharing!|

{I really|I truly|I seriously|I absolutely} love {your blog|your site|your website}..

{Very nice|Excellent|Pleasant|Great} colors & theme.

Did you {create|develop|make|build} {this website|this site|this web site|this

amazing site} yourself? Please reply back as I'm {looking

to|trying to|planning to|wanting to|hoping to|attempting to} create {my own|my

very own|my own personal} {blog|website|site} and

{would like to|want to|would love to} {know|learn|find

out} where you got this from or {what the|exactly

what the|just what the} theme {is called|is named}.

{Thanks|Many thanks|Thank you|Cheers|Appreciate it|Kudos}!|

{Hi there|Hello there|Howdy}! This {post|article|blog post} {couldn't|could not} be written {any better|much better}!

{Reading through|Looking at|Going through|Looking through} this {post|article}

reminds me of my previous roommate! He {always|constantly|continually} kept {talking about|preaching about} this.

{I will|I'll|I am going to|I most certainly will} {forward|send} {this article|this information|this post} to him.

{Pretty sure|Fairly certain} {he will|he'll|he's

going to} {have a good|have a very good|have a great} read.

{Thank you for|Thanks for|Many thanks for|I appreciate you for} sharing!|

{Wow|Whoa|Incredible|Amazing}! This blog looks {exactly|just} like my old one!

It's on a {completely|entirely|totally} different {topic|subject} but it has pretty much the same {layout|page layout} and

design. {Excellent|Wonderful|Great|Outstanding|Superb} choice

of colors!|

{There is|There's} {definately|certainly} {a lot to|a great deal to} {know about|learn about|find out

about} this {subject|topic|issue}. {I like|I love|I really like} {all the|all of the} points {you made|you've made|you

have made}.|

{You made|You've made|You have made} some {decent|good|really good} points there.

I {looked|checked} {on the internet|on the web|on the net} {for more info|for more

information|to find out more|to learn more|for additional information} about the issue and found {most individuals|most people} will go along

with your views on {this website|this site|this web site}.|

{Hi|Hello|Hi there|What's up}, I {log on to|check|read} your {new stuff|blogs|blog} {regularly|like every week|daily|on a regular basis}.

Your {story-telling|writing|humoristic} style is {awesome|witty}, keep {doing what you're

doing|up the good work|it up}!|

I {simply|just} {could not|couldn't} {leave|depart|go away} your {site|web

site|website} {prior to|before} suggesting that I {really|extremely|actually} {enjoyed|loved}

{the standard|the usual} {information|info} {a person|an individual} {supply|provide} {for your|on your|in your|to your} {visitors|guests}?

Is {going to|gonna} be {back|again} {frequently|regularly|incessantly|steadily|ceaselessly|often|continuously} {in order to|to} {check up on|check out|inspect|investigate cross-check}

new posts|

{I wanted|I needed|I want to|I need to} to thank you for this {great|excellent|fantastic|wonderful|good|very good} read!!

I {definitely|certainly|absolutely} {enjoyed|loved}

every {little bit of|bit of} it. {I have|I've got|I have got} you {bookmarked|book marked|book-marked|saved as a favorite} {to check out|to look at} new {stuff you|things you} post…|

{Hi|Hello|Hi there|What's up}, just wanted to {mention|say|tell you}, I {enjoyed|liked|loved} this {article|post|blog post}.

It was {inspiring|funny|practical|helpful}. Keep on posting!|

{Hi there|Hello}, I enjoy reading {all of|through} your {article|post|article post}.

I {like|wanted} to write a little comment to support you.|

I {always|constantly|every time} spent my half an hour to read this {blog|weblog|webpage|website|web site}'s {articles|posts|articles or reviews|content} {everyday|daily|every day|all the time} along with a {cup|mug} of coffee.|

I {always|for all time|all the time|constantly|every time} emailed this {blog|weblog|webpage|website|web

site} post page to all my {friends|associates|contacts}, {because|since|as|for the reason that} if like to read it {then|after that|next|afterward} my {friends|links|contacts} will too.|

My {coder|programmer|developer} is trying to {persuade|convince} me to move to .net from PHP.

I have always disliked the idea because of the {expenses|costs}.

But he's tryiong none the less. I've been using {Movable-type|WordPress} on {a

number of|a variety of|numerous|several|various} websites for about a year and am {nervous|anxious|worried|concerned} about switching to another platform.

I have heard {fantastic|very good|excellent|great|good} things about blogengine.net.

Is there a way I can {transfer|import} all my wordpress

{content|posts} into it? {Any kind of|Any} help would be {really|greatly} appreciated!|

{Hello|Hi|Hello there|Hi there|Howdy|Good day}! I could have sworn I've {been to|visited} {this blog|this web

site|this website|this site|your blog} before but after {browsing through|going through|looking at} {some of the|a few of the|many of the} {posts|articles} I realized it's

new to me. {Anyways|Anyhow|Nonetheless|Regardless}, I'm {definitely|certainly}

{happy|pleased|delighted} {I found|I discovered|I came across|I stumbled upon} it and I'll be {bookmarking|book-marking} it and checking back {frequently|regularly|often}!|

{Terrific|Great|Wonderful} {article|work}! {This is|That

is} {the type of|the kind of} {information|info} {that are meant to|that are supposed to|that should}

be shared {around the|across the} {web|internet|net}. {Disgrace|Shame}

on {the {seek|search} engines|Google} for {now not|not|no longer} positioning this {post|submit|publish|put up} {upper|higher}!

Come on over and {talk over with|discuss with|seek advice from|visit|consult with} my {site|web site|website} .

{Thank you|Thanks} =)|

Heya {i'm|i am} for the first time here. I {came across|found}

this board and I find It {truly|really} useful

& it helped me out {a lot|much}. I hope to give something

back and {help|aid} others like you {helped|aided} me.|

{Hi|Hello|Hi there|Hello there|Howdy|Greetings}, {I think|I believe|I

do believe|I do think|There's no doubt that} {your site|your website|your web site|your

blog} {might be|may be|could be|could possibly be} having {browser|internet browser|web browser} compatibility {issues|problems}.

{When I|Whenever I} {look at your|take a look at your} {website|web site|site|blog} in Safari, it looks fine {but when|however when|however, if|however, when} opening in {Internet Explorer|IE|I.E.}, {it

has|it's got} some overlapping issues. {I just|I simply|I merely} wanted

to {give you a|provide you with a} quick heads up!

{Other than that|Apart from that|Besides that|Aside from

that}, {fantastic|wonderful|great|excellent} {blog|website|site}!|

{A person|Someone|Somebody} {necessarily|essentially} {lend a hand|help|assist} to make

{seriously|critically|significantly|severely} {articles|posts} {I would|I might|I'd} state.

{This is|That is} the {first|very first} time I frequented your {web page|website

page} and {to this point|so far|thus far|up to now}?

I {amazed|surprised} with the {research|analysis} you made to {create|make} {this actual|this particular} {post|submit|publish|put up} {incredible|amazing|extraordinary}.

{Great|Wonderful|Fantastic|Magnificent|Excellent} {task|process|activity|job}!|

Heya {i'm|i am} for {the primary|the first} time here. I {came across|found} this board and I

{in finding|find|to find} It {truly|really} {useful|helpful} & it helped me out {a lot|much}.

{I am hoping|I hope|I'm hoping} {to give|to offer|to

provide|to present} {something|one thing} {back|again} and

{help|aid} others {like you|such as you} {helped|aided} me.|

{Hello|Hi|Hello there|Hi there|Howdy|Good day|Hey there}!

{I just|I simply} {would like to|want to|wish to} {give you a|offer you

a} {huge|big} thumbs up {for the|for your} {great|excellent} {info|information} {you

have|you've got|you have got} {here|right here} on this post.

{I will be|I'll be|I am} {coming back to|returning to} {your

blog|your site|your website|your web site} for more soon.|

I {always|all the time|every time} used to {read|study}

{article|post|piece of writing|paragraph} in news papers but now as I am

a user of {internet|web|net} {so|thus|therefore} from now I am using net for {articles|posts|articles or reviews|content},

thanks to web.|

Your {way|method|means|mode} of {describing|explaining|telling}

{everything|all|the whole thing} in this {article|post|piece of writing|paragraph} is {really|actually|in fact|truly|genuinely}

{nice|pleasant|good|fastidious}, {all|every one} {can|be able to|be capable of} {easily|without difficulty|effortlessly|simply} {understand|know|be aware of} it, Thanks

a lot.|

{Hi|Hello} there, {I found|I discovered} your {blog|website|web site|site} {by means of|via|by the use

of|by way of} Google {at the same time as|whilst|even as|while} {searching for|looking for} a {similar|comparable|related} {topic|matter|subject}, your {site|web site|website} {got here|came} up, it {looks|appears|seems|seems to be|appears to be

like} {good|great}. {I have|I've} bookmarked it in my google bookmarks.

{Hello|Hi} there, {simply|just} {turned into|became|was|become|changed

into} {aware of|alert to} your {blog|weblog} {thru|through|via} Google,

{and found|and located} that {it is|it's} {really|truly} informative.

{I'm|I am} {gonna|going to} {watch out|be careful} for brussels.

{I will|I'll} {appreciate|be grateful} {if you|should you|when you|in the event you|in case you|for those who|if you happen to} {continue|proceed} this {in future}.

{A lot of|Lots of|Many|Numerous} {other folks|folks|other people|people}

{will be|shall be|might be|will probably be|can be|will likely be} benefited

{from your|out of your} writing. Cheers!|

{I am|I'm} curious to find out what blog {system|platform} {you have been|you happen to be|you are|you're} {working with|utilizing|using}?

I'm {experiencing|having} some {minor|small} security {problems|issues} with my latest {site|website|blog} and {I would|I'd} like

to find something more {safe|risk-free|safeguarded|secure}.

Do you have any {solutions|suggestions|recommendations}?|

{I am|I'm} {extremely|really} impressed with your writing skills {and also|as well as}

with the layout on your {blog|weblog}. Is this a paid theme or

did you {customize|modify} it yourself? {Either way|Anyway} keep up the

{nice|excellent} quality writing, {it's|it is} rare to see a {nice|great} blog like this one {these days|nowadays|today}.|

{I am|I'm} {extremely|really} {inspired|impressed} {with your|together with your|along with

your} writing {talents|skills|abilities} {and also|as {smartly|well|neatly} as} with

the {layout|format|structure} {for your|on your|in your|to your}

{blog|weblog}. {Is this|Is that this} a paid {subject|topic|subject

matter|theme} or did you {customize|modify} it {yourself|your self}?

{Either way|Anyway} {stay|keep} up the {nice|excellent}

{quality|high quality} writing, {it's|it is} {rare|uncommon} {to peer|to see|to look} a {nice|great} {blog|weblog} like

this one {these days|nowadays|today}..|

{Hi|Hello}, Neat post. {There is|There's} {a problem|an issue} {with your|together

with your|along with your} {site|web site|website} in {internet|web} explorer, {may|might|could|would} {check|test} this?

IE {still|nonetheless} is the {marketplace|market} {leader|chief} and {a large|a good|a big|a huge} {part of|section of|component to|portion of|component of|element of} {other

folks|folks|other people|people} will {leave out|omit|miss|pass over} your

{great|wonderful|fantastic|magnificent|excellent} writing {due to|because of} this problem.|

{I'm|I am} not sure where {you are|you're} getting your

{info|information}, but {good|great} topic. I needs to spend some time learning {more|much more} or understanding more.

Thanks for {great|wonderful|fantastic|magnificent|excellent} {information|info} I was looking for this {information|info} for my mission.|

{Hi|Hello}, i think that i saw you visited my {blog|weblog|website|web

site|site} {so|thus} i came to “return the favorâ€.{I am|I'm} {trying to|attempting to} find things to {improve|enhance} my

{website|site|web site}!I suppose its ok to use {some of|a few of} your

ideas!!

\

Posted by: customized bobble head at July 22, 2015 09:47 AM (A1nsC)

35

For newest news you have to visit web and on the web I found

this website as a most excellent web site for latest updates.

Posted by: cheap fake ray bans at July 23, 2015 11:39 AM (jrXLt)

36

craigslist phone verified accounts on sale :

$4 per account contact to buy - Yahoo Messenger - anjudevianju skype - anjudevi

www.freshPVA.com Instant Delivery.

Also we are undertaking re-verification of craigslist phone verified accountse been surfing online more than three hours these

days, but I by no means found any fascinating article like yours.

It's beautiful value sufficient for me. In my view, if all webmasters and bloggers made

just right content material as you did, the internet might be much more helpful than ever before.|

Ahaa, its pleasant discussion about this piece of writing here at this website,

I have read all that, so now me also commenting at this place.|

I am sure this paragraph has touched all the internet people,

its really really nice article on building up new website.|

Wow, this post is good, my younger sister is analyzing these things, so I am going to let know her.|

Saved as a favorite, I like your website!|

Way cool! Some very valid points! I appreciate you penning this write-up plus the rest of the site is also very good.|

Hi, I do think this is an excellent site. I stumbledupon it

I'm going to return

yet again since I book-marked it. Money and freedom is the best way to

change, may you be rich and continue to help others.|

Woah! I'm really digging the template/theme

of this site. It's simple, yet effective. A lot of times it's very hard to get that "perfect balance" between usability and appearance.

I must say you have done a very good job with this.

Additionally, the blog loads extremely fast for me on Internet explorer.

Exceptional Blog!|

These are actually fantastic ideas in regarding blogging. You have

touched some nice points here. Any way keep up wrinting.|

I really like what you guys tend to be up too. This type of clever work and reporting!

Keep up the wonderful works guys I've you guys to my personal blogroll.|

Howdy! Someone in my Myspace group shared this website with us so

I came to check it out. I'm definitely loving the information.

I'm book-marking and will be tweeting this to my followers!

Fantastic blog and wonderful design.|

I really like what you guys are usually up too. This kind of clever work and reporting!

Keep up the great works guys I've incorporated you guys to my own blogroll.|

Hey there would you mind sharing which blog platform you're working with?

I'm going to start my own blog in the near future but I'm having a difficult time choosing between BlogEngine/Wordpress/B2evolution and

Drupal. The reason I ask is because your design and style seems different then most blogs and I'm looking for something completely unique.

P.S Apologies for being off-topic but I had to ask!|

Hey would you mind letting me know which webhost you're using?

I've loaded your blog in 3 completely different browsers and I

must say this blog loads a lot faster then most. Can you suggest a good web hosting

provider at a honest price? Kudos, I appreciate it!|

I like it when folks get together and share opinions. Great blog, keep it up!|

Thank you for the good writeup. It in fact was a amusement account it.

Look advanced to more added agreeable from you! By the way, how could we communicate?|

Howdy just wanted to give you a quick heads up. The text in your article seem to

be running off the screen in Firefox. I'm not sure if this is

a format issue or something to do with browser compatibility but I

figured I'd post to let you know. The style and design look great though!

Hope you get the problem resolved soon. Thanks|

This is a topic which is close to my heart... Take care!

Exactly where are your contact details though?|

It's very trouble-free to find out any matter on net as

compared to books, as I found this post at this web site.|

Does your blog have a contact page? I'm having trouble locating it but, I'd like

to send you an email. I've got some ideas for your blog you might be interested in hearing.

Either way, great website and I look forward to seeing it grow over

time.|

Hi! I've been following your site for a long time now and finally got the courage to go ahead and give you a

shout out from Houston Texas! Just wanted to tell you keep up the great work!|

Greetings from Carolina! I'm bored to death at work

so I decided to browse your blog on my iphone during lunch break.

I really like the information you provide here and can't wait to take a look when I get home.

I'm amazed at how fast your blog loaded on my phone .. I'm not even using

WIFI, just 3G .. Anyways, amazing site!|

Its like you learn my thoughts! You seem to grasp a lot approximately this, like

you wrote the guide in it or something. I believe that you simply could do with a few percent to power the

message home a bit, however instead of that, that is fantastic blog.

An excellent read. I'll certainly be back.|

I visited various blogs except the audio quality for audio songs current

at this website is really marvelous.|

Howdy, i read your blog from time to time and i own a similar one and i was just curious

if you get a lot of spam remarks? If so how do you reduce it, any

plugin or anything you can advise? I get so much lately it's driving me insane so any help is very much appreciated.|

Greetings! Very helpful advice in this particular post!

It is the little changes that produce the biggest changes.

Many thanks for sharing!|

I really love your blog.. Great colors & theme. Did you develop this website

yourself? Please reply back as I'm planning to create my own site and want to know where you got this from or exactly

what the theme is named. Many thanks!|

Hi there! This post could not be written

any better! Reading through this post reminds me of my previous roommate!

He continually kept preaching about this. I most certainly will forward this information to him.

Fairly certain he will have a great read. Thanks for sharing!|

Incredible! This blog looks just like my old one! It's on a

completely different subject but it has pretty much the same page layout and design.

Great choice of colors!|

There's definately a great deal to learn about this topic.

I really like all the points you have made.|

You have made some decent points there. I checked on the internet to learn more about the issue and

found most individuals will go along with your views on this web site.|

What's up, I read your new stuff on a regular basis. Your story-telling style is witty,

keep up the good work!|

I just couldn't go away your site prior to suggesting that

I really enjoyed the standard information a person provide on your visitors?

Is gonna be back continuously in order to check out new

posts|

I needed to thank you for this fantastic read!! I absolutely enjoyed every bit of it.

I've got you bookmarked to look at new things you post…|

What's up, just wanted to tell you, I loved this blog post.

It was helpful. Keep on posting!|

I drop a comment each time I appreciate a post on a blog or I have something to valuable to contribute to the

discussion. Usually it is caused by the fire communicated in the

post I looked at. And on this post Fiber optic cable.

I was excited enough to drop a comment

I actually do have some questions

for you if it's okay. Could it be only me or does it look like like some of the comments appear like coming

from brain dead folks? :-P And, if you are writing at additional online social sites, I would like to follow you.

Could you list all of all your communal sites like your Facebook page, twitter feed, or linkedin profile?|

Hi there, I enjoy reading all of your article.

I wanted to write a little comment to support

you.|

I every time spent my half an hour to read this web site's

posts every day along with a cup of coffee.|

I for all time emailed this weblog post page to all my friends, since if like to read it next my links will too.|

My coder is trying to persuade me to move to .net from PHP.

I have always disliked the idea because of the costs. But he's tryiong none the less.

I've been using WordPress on several websites for about

a year and am anxious about switching to another platform.

I have heard great things about blogengine.net. Is there a way I

can transfer all my wordpress posts into it?

Any help would be really appreciated!|

Hello there! I could have sworn I've visited this

web site before but after going through many of the articles

I realized it's new to me. Regardless, I'm certainly happy

I came across it and I'll be bookmarking it and checking back regularly!|

Great article! That is the kind of information that are meant to be

shared across the internet. Shame on Google for no longer positioning this post upper!

Come on over and visit my web site . Thanks =)|

Heya i am for the first time here. I came across this board and I find It really useful &

it helped me out a lot. I hope to give something back and aid others like you

aided me.|

Hi, I do think your web site may be having web browser compatibility issues.

When I look at your blog in Safari, it looks fine however,

when opening in IE, it's got some overlapping issues. I simply wanted

to provide you with a quick heads up! Aside from that, great blog!|

Someone essentially help to make critically posts I

would state. This is the first time I frequented your website page and so far?

I amazed with the analysis you made to make this actual submit incredible.

Wonderful process!|

Heya i am for the primary time here. I found this board and I in finding It really useful & it helped me out

a lot. I am hoping to offer something again and aid others such as you helped me.|

Hi! I simply would like to give you a big thumbs up for your excellent information you have right here on this post.

I will be returning to your web site for more soon.|

I all the time used to read paragraph in news papers but now as

I am a user of web so from now I am using net for articles or reviews, thanks to web.|

Your method of telling the whole thing in this post is really

fastidious, all can without difficulty be aware of it,

Thanks a lot.|

Hi there, I found your web site via Google whilst searching for a comparable

topic, your web site came up, it seems great. I've bookmarked it in my google

bookmarks.

Hi there, just was alert to your weblog thru Google, and found that

it's truly informative. I am gonna be careful for brussels.

I will appreciate if you happen to proceed this in future.

Many people will be benefited from your writing.

Cheers!|

I am curious to find out what blog system you're utilizing?

I'm having some small security issues with my latest blog and I would like to

find something more secure. Do you have any solutions?|

I'm really impressed with your writing skills and also with the layout on your weblog.

Is this a paid theme or did you customize it yourself? Either way keep

up the excellent quality writing, it's rare to see a

nice blog like this one today.|

I'm extremely impressed together with your writing abilities

and also with the structure to your weblog. Is that this a paid subject matter or did you modify it

yourself? Either way keep up the excellent high quality writing, it is uncommon to peer a great weblog like this

one these days..|

Hello, Neat post. There is an issue along

with your site in internet explorer, would check this?

IE still is the marketplace leader and a big component of other folks will pass over your excellent writing due

to this problem.|

I am not sure where you're getting your info, but good topic.

I needs to spend some time learning much more or understanding

more. Thanks for great information I was looking for this information for my

mission.|

Hello, i think that i saw you visited my weblog so i came

to “return the favorâ€.I'm trying to find things to enhance my website!I suppose its ok to use a few of your

ideas!!|

Hi, i feel that i saw you visited my site thus i came to go back the choose?.I

am trying to to find issues to improve my site!I assume its ok to

use a few of your ideas!!|

Hi there, just became alert to your blog through Google, and found that it's really informative.

I'm gonna watch out for brussels. I will be grateful if you continue

this in future. Lots of people will be benefited from your

writing. Cheers!|

I am now not sure the place you're getting your

information, but great topic. I must spend some time finding out more or understanding more.

Thanks for magnificent information I used to be on the lookout for this info for my mission.|

Hello my family member! I wish to say that this article is amazing, great

written and include approximately all vital infos.

I'd like to peer extra posts like this .|

hello!,I like your writing so a lot! proportion we keep up

a correspondence extra approximately your post on AOL?

I require an expert in this space to solve my problem.

May be that is you! Looking ahead to look you. |

I'm really loving the theme/design of your weblog.

Do you ever run into any browser compatibility issues? A few

of my blog readers have complained about my site not

operating correctly in Explorer but looks great in Opera.

Do you have any suggestions to help fix this issue?|

Great info. Lucky me I discovered your site by chance (stumbleupon).

I have book marked it for later!|

It's impressive that you are getting thoughts from this article as well as from our argument made at this time.|

If you wish for to improve your knowledge simply keep visiting this web site and be

updated with the hottest news update posted

here.|

What's Taking place i'm new to this, I stumbled upon this

I've discovered It positively helpful and it has helped me out loads.

I am hoping to contribute & assist other users like its helped me.

Great job.|

Hurrah, that's what I was searching for, what a stuff!

existing here at this webpage, thanks admin of this web page.|

If you want to obtain a good deal from this post then you have to apply these

techniques to your won webpage.|

It's an awesome article designed for all the internet

visitors; they will take advantage from it I am sure.|

I have learn several excellent stuff here. Certainly price bookmarking for revisiting.

I surprise how a lot attempt you place to create this type of

excellent informative website.|

This is a very good tip especially to those fresh to

the blogosphere. Brief but very precise information… Many thanks for sharing this one.

A must read post!|

I've been exploring for a little for any high-quality articles or

blog posts in this kind of house . Exploring in Yahoo I eventually stumbled upon this site.

Studying this info So i'm glad to convey that I have a very good uncanny feeling I found out

exactly what I needed. I so much undoubtedly will

make certain to don?t forget this website and give it a glance on a constant basis.|

Having read this I believed it was very enlightening. I

appreciate you taking the time and effort to put this informative article together.

I once again find myself personally spending a significant

amount of time both reading and commenting.

But so what, it was still worthwhile!|

Quality content is the key to be a focus for the viewers to pay a quick visit the site, that's what this

site is providing.|

Link exchange is nothing else however it is simply placing the other person's weblog link

on your page at suitable place and other person

will also do same for you.|

I have read so many articles concerning the blogger lovers

but this paragraph is in fact a pleasant article,

keep it up.|

Really when someone doesn't understand afterward its up to

other people that they will help, so here it happens.|

You can definitely see your enthusiasm in the work you write.

The arena hopes for more passionate writers such as

you who are not afraid to mention how they believe.

Always follow your heart.|

Excellent post. I'm going through many of these issues as well..|

Excellent web site you have here.. It's hard to find high-quality writing like yours nowadays.

I honestly appreciate individuals like you!

Take care!!|

I was recommended this website by my cousin. I'm not sure

whether this post is written by him as no one else know such detailed about my problem.

You are amazing! Thanks!|

Good article! We are linking to this particularly great post on our

website. Keep up the great writing.|

Oh my goodness! Amazing article dude! Thank you, However I am going through issues with your RSS.

I don't understand the reason why I am unable to join

it. Is there anyone else getting similar RSS issues?

Anybody who knows the answer can you kindly respond?

Thanks!!|

Amazing blog! Do you have any tips and hints for aspiring writers?

I'm hoping to start my own site soon but I'm a little lost on everything.

Would you suggest starting with a free platform like Wordpress or go for a paid option?

There are so many choices out there that I'm totally confused ..

Any tips? Kudos!|

It's difficult to find knowledgeable people about this subject,

however, you sound like you know what you're talking about!

Thanks|

I don't even know the way I stopped up here, but I believed this

put up was once good. I don't recognise who you might

be but definitely you're going to a well-known blogger if you

are not already. Cheers!|

Fastidious respond in return of this matter with genuine arguments and telling everything regarding that.|

I don't even know how I ended up here, but I thought this post was great.

I do not know who you are but certainly you're going to a famous blogger if

you aren't already

Cheers!|

We are a gaggle of volunteers and starting a brand new scheme in our community.

Your site offered us with valuable info to work on.

You've performed an impressive activity and our entire neighborhood will probably be grateful to you.|

Fine way of describing, and nice piece of writing to obtain facts regarding my presentation focus, which

i am going to deliver in academy.|

Great blog right here! Also your web site a lot up very

fast! What web host are you the usage of? Can I get your affiliate

hyperlink to your host? I wish my website loaded up as fast as yours lol|

I love your blog.. very nice colors & theme.

Did you design this website yourself or did you hire someone to do it for you?

Plz reply as I'm looking to construct my own blog and would like to know where u got this from.

thanks a lot|

We're a group of volunteers and starting a new scheme in our community.

Your web site provided us with valuable info to work on. You

have done an impressive job and our whole community will be grateful to

you.|

Appreciate this post. Will try it out.|

Asking questions are truly good thing if you are

not understanding anything fully, but this piece of

writing presents good understanding even.|

Have you ever considered about including a little

bit more than just your articles? I mean, what you say is important

and everything. However think of if you added some great visuals or video clips to give your posts more, "pop"!

Your content is excellent but with pics and videos, this website could undeniably be one of the best in its niche.

Great blog!|

Your style is unique compared to other people I've read stuff from.

I appreciate you for posting when you have the opportunity, Guess I will just bookmark this page.|

Very nice post. I simply stumbled upon your blog and wished to mention that I have really

enjoyed surfing around your blog posts. After all I will be subscribing

in your rss feed and I am hoping you write once more soon!|

I'm impressed, I must say. Seldom do I come across a blog that's both

equally educative and engaging, and without a doubt, you've hit the nail on the head.

The issue is something that not enough folks are speaking intelligently about.

I'm very happy that I found this in my search for something relating

to this.|

Hmm it seems like your blog ate my first comment (it was extremely long) so I guess I'll just sum

it up what I wrote and say, I'm thoroughly enjoying your blog.

I too am an aspiring blog writer but I'm still new to everything.

Do you have any points for inexperienced blog writers?

I'd really appreciate it.|

Very nice post. I just stumbled upon your weblog and wished to say that I have really enjoyed browsing your

blog posts. After all I will be subscribing to your feed and I hope

you write again very soon!|

I like the helpful information you provide in your articles.

I'll bookmark your weblog and check again here frequently.

I am quite sure I will learn a lot of new stuff right here!

Good luck for the next!|

If you are going for most excellent contents like I do, simply pay a

quick visit this web site everyday since it presents feature contents,

thanks|

Write more, thats all I have to say. Literally, it seems as though you relied

on the video to make your point. You definitely know what youre talking about,

why waste your intelligence on just posting videos to your blog

when you could be giving us something enlightening to read?|

Highly descriptive post, I enjoyed that bit.

Will there be a part 2?|

Excellent post. I used to be checking constantly this weblog and I am impressed!

Extremely useful info specifically the last phase :

) I maintain such information much. I was looking for this particular information for a very lengthy time.

Thanks and best of luck. |

Nice post. I was checking constantly this blog and I'm impressed!

Very useful information particularly the last part :

) I care for such info much. I was looking for this certain information

for a very long time. Thank you and best of luck.|

Great post.|

After looking over a handful of the blog articles on your blog, I truly appreciate

your technique of blogging. I book marked it to my bookmark site list and will be checking back in the

near future. Take a look at my website too and tell me your opinion.|

A motivating discussion is worth comment. I believe that you ought to publish more about this issue,

it might not be a taboo matter but typically folks don't talk about such issues.

To the next! Kind regards!!|

certainly like your web site however you need to take a look at

the spelling on quite a few of your posts. Many of them are rife with spelling problems and I to find it

very troublesome to tell the truth then again I will surely come

again again.|

I do agree with all of the ideas you have offered in your post.

They're really convincing and can definitely work.

Nonetheless, the posts are very quick for starters. May just you please extend them a little from subsequent time?

Thanks for the post.|

We stumbled over here from a different page and thought I might check things out.

I like what I see so now i am following you. Look forward to exploring your web page for a second time.|

Very good blog post. I definitely love this site. Keep it up!|

Have you ever considered creating an ebook or guest authoring

on other sites? I have a blog based upon on the same topics you discuss and would love to have you share some stories/information.

I know my visitors would appreciate your work. If

you're even remotely interested, feel free to shoot me an e-mail.|

My partner and I stumbled over here from a different website and thought I should check things out.